Li-teminals tse phahameng tsa koporo tsa PCB le li-screw terminals

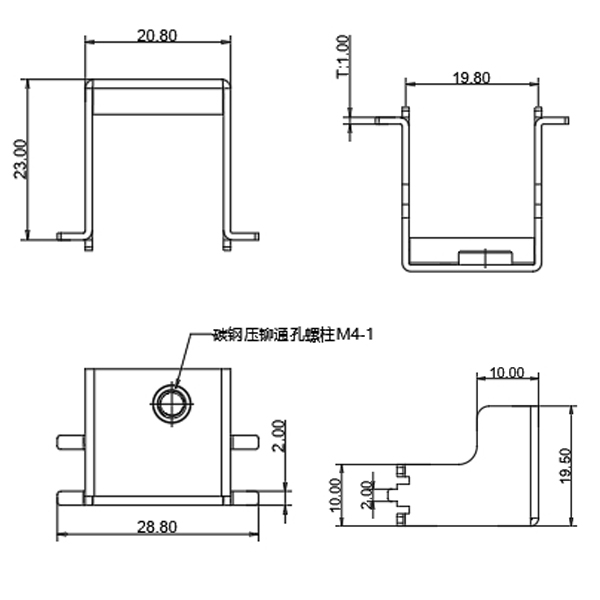

Litšoantšo tsa lihlahisoa

Lisebelisoa tsa lihlahisoa tsa Copper Tube Terminals

| Sebaka sa Tšimoloho: | Guangdong, China | Mmala: | silevera | ||

| Lebitso la Brand: | haocheng | Boitsebiso: | Koporo/ koporo | ||

| Nomoro ea Mohlala: | 753008001 | Kopo: | Lisebelisoa tsa lapeng. Likoloi. Lipuisano. Matla a macha. Lebone | ||

| Mofuta: | PCB welding terminal | Sephutheloana: | Mabokose a Tloaelehileng | ||

| Lebitso la sehlahisoa: | PCB welding terminal | MOQ: | 10000 li-PC | ||

| Phekolo ea sefahleho: | customisable | Ho paka: | 1000 li-PC | ||

| Sebaka sa marang-rang: | customisable | Boholo: | customisable | ||

| Nako ea ho etella pele: Nako ea nako ho tloha ha odara e beoa ho isa ho e rometsoeng | Bongata (likotoana) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Nako ea ho tsamaisa (matsatsi) | 10 | 15 | 30 | Ho buisanoa | |

Melemo ea li-terminals tsa Copper Tube

1. Khokahano ea motlakase e tšepahalang

Khahlano e tlaase ea ho kopana: Li-terminals li entsoe ka thepa e phahameng haholo (e kang alloy ea koporo) ho etsa bonnete ba hore phetisetso e tsitsitseng ea hona joale le ho fokotsa tahlehelo ea matla.

Matla a ho tjheselletsa tjheseletsa: Moralo wa tjheseletsa o tiisa kgokahanyo e tiileng pakeng tsa boto le boto ya PCB, o fokotsa kotsi ya ho tjheseletsa ho batang le ho tjheseletsa ho robehileng, mme o ntlafatsa ho tiya ha sehlahiswa.

2. Matla a phahameng a mechine

Khanyetso e ntle ea vibrate: E loketse lisebelisoa tse hlokang ho mamella ho thothomela le tšusumetso, joalo ka taolo ea indasteri, li-module tsa motlakase, jj.

Bophelo ba plug-in e phahameng: E loketse lits'ebetso tse nang le li-plug-in khafetsa le tse hulang, tse ntlafatsang botsitso le botsitso ba li-terminals.

3. Ho mamella mocheso o phahameng

Thepa e hanyetsanang le mocheso o phahameng: Li-terminals tse ling li phuthetsoe ka thini kapa ka khauta, 'me li khona ho mamella mekhoa ea ho cheselletsa mocheso o phahameng (joaloka wave soldering le reflow soldering).

E loketse libaka tse thata: E loketse libaka tse nang le liphetoho tse kholo tsa mocheso, joalo ka lisebelisoa tsa elektroniki tsa likoloi, lisebelisoa tsa motlakase, jj.

4. Ho lumellana ho matla

Ikamahanya le maemo a fapaneng PCB botenya: Terminals ea litlhaloso tse fapa-fapaneng ka fanoa ho ea ka ditiriso fapaneng, 'me a loketse bakeng sa mapolanka a sa tšoaneng PCB.

E loketse bakeng sa welding e ikemetseng: E ts'ehetsa lits'ebetso tsa tlhahiso ea boiketsetso joalo ka SMT le DIP ho ntlafatsa katleho ea tlhahiso.

5. Mekhoa e mengata ea phekolo e fumanehang

Tin plating: e ntlafatsa ts'ebetso ea welding, e thibela oxidation, hape e ntlafatsa ho hanyetsa kutu.

Ho roala khauta: ho fokotsa khanyetso ea ho kopana, ho ntlafatsa khanyetso ea oxidation, 'me e loketse lihlahisoa tsa elektronike tse phahameng.

Silver plating: e ntlafatsa conductivity le mocheso o phahameng oa ho hanyetsa, 'me e loketse lipotoloho tse matla a phahameng.

6. Mehaho e fapaneng le lits'ebetso tse tenyetsehang

Mekhoa e mengata ea ho kenya: joalo ka plug e otlolohileng, plug ea bend, mount mount, joalo-joalo, e ka fihlela litlhoko tse fapaneng tsa moralo oa PCB.

Maqhubu a fapaneng a lekantsoeng a fumaneha: a loketse phetisetso ea lets'oao le tlase kapa lisebelisoa tse phahameng tsa phepelo ea motlakase.

7. Botala le tikoloho

RoHS e lumellana: ho sebelisa thepa e baballang tikoloho le ho latela melaoana ea machaba ea tikoloho.

Tšehetso ea solder e tlaase le e se nang loto: e finyella litlhoko tsa tlhahiso ea tikoloho 'me e loketse limmaraka tse phahameng.

Lilemo tse 18+ tsa Copper Tube Terminals Cnc Machining Experience

• Liphihlelo tsa R&D tsa Lilemo tse 18 nakong ea selemo, setempe sa tšepe le likarolo tsa CNC.

• Boenjiniere ba litsebo le botekgeniki ho netefatsa boleng.

•Ho tsamaisoa ka nako

• Boiphihlelo ba lilemo ba ho sebelisana le li-brand tse holimo.

• Mefuta e fapaneng ea mochini oa tlhahlobo le tlhahlobo bakeng sa netefatso ea boleng.

LIKOPO

Likoloi

lisebelisoa tsa lapeng

libapalisoa

li-switches tsa matla

lihlahisoa tsa elektronike

mabone a deske

lebokose la kabo E sebetsa ho

Lithapo tsa motlakase ka lisebelisoa tsa kabo ea matla

Lithapo tsa motlakase le lisebelisoa tsa motlakase

Khokahano bakeng sa

sefefo sa maqhubu

Likoloi tse ncha tsa matla

Moetsi oa likarolo tsa lisebelisoa tsa thepa e le 'ngoe

1, Puisano ea bareki:

Utloisisa litlhoko tsa bareki le litlhaloso tsa sehlahisoa.

2. Moralo oa sehlahisoa:

Etsa moralo o ipapisitseng le litlhoko tsa bareki, ho kenyeletsoa lisebelisoa le mekhoa ea tlhahiso.

3, Tlhahiso:

Etsa sehlahisoa u sebelisa mekhoa e nepahetseng ea tšepe e kang ho itšeha, ho cheka, ho sila, joalo-joalo.

4, Kalafo ea holim'a metsi:

Sebelisa lisebelisoa tse nepahetseng tsa bokaholimo joalo ka ho fafatsa, electroplating, kalafo ea mocheso, jj.

5, Taolo ea boleng:

Hlahloba le ho netefatsa hore lihlahisoa li finyella litekanyetso tse boletsoeng.

6, Logistics:

Lokisetsa lipalangoang bakeng sa ho isoa ka nako ho bareki.

7, Ka mor'a-thekiso tšebeletso:

Fana ka tšehetso le ho rarolla mathata afe kapa afe a bareki.

LBH

A: Re feme.

A: Ka kakaretso matsatsi a 5-10 haeba thepa e le teng. Matsatsi a 7-15 haeba thepa e le sieo, ka bongata.

A: E, haeba re na le lisampole setokong, re ka fana ka mehlala. Litefiso tse amanang le tsona li tla tlaleheloa uena.

A: E itšetlehile ka bongata ba taelo le ha u beha taelo.