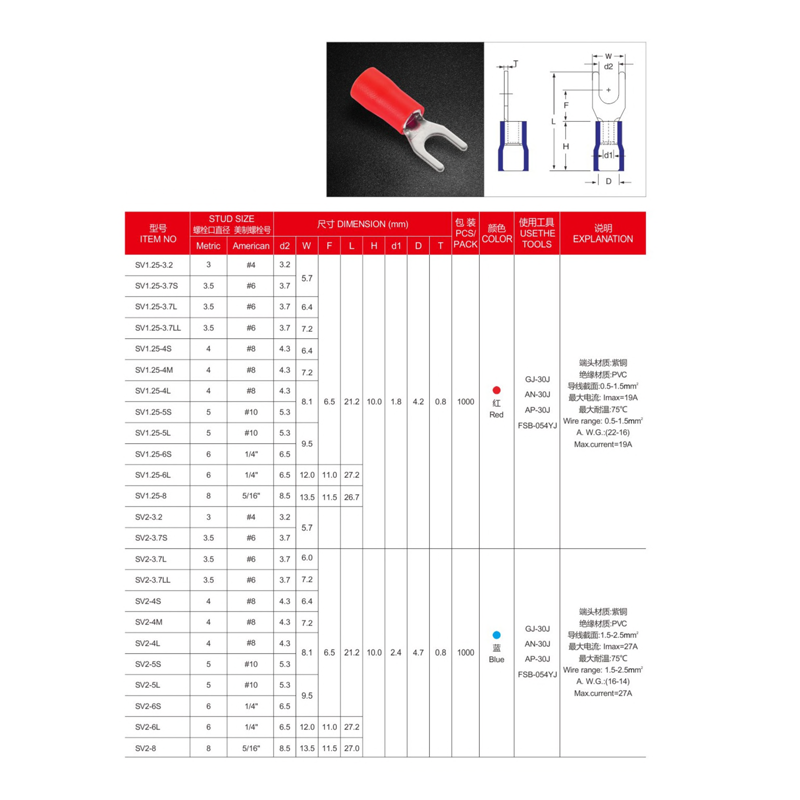

FORK SHAPE PREINSULATION TERMINAL

Lisebelisoa tsa lihlahisoa tsa Copper Tube Terminals

| Sebaka sa Tšimoloho: | Guangdong, China | Mmala: | silevera | |||

| Lebitso la Brand: | haocheng | Boitsebiso: | Koporo | |||

| Nomoro ea Mohlala: | SV1.25-SV5.5 | Kopo: | Khokahano ea Mohala | |||

| Mofuta: | FORKSHAPE PREINSULATION TERMINAL | Sephutheloana: | Mabokose a Tloaelehileng | |||

| Lebitso la sehlahisoa: | Crimp Terminal | MOQ: | 1000 li-PC | |||

| Phekolo ea sefahleho: | customisable | Ho paka: | 1000 li-PC | |||

| Sebaka sa marang-rang: | customisable | Boholo: | 21.5-31 limilimithara | |||

| Nako ea ho etella pele: Nako ea nako ho tloha ha odara e beoa ho isa ho e rometsoeng | Bongata (likotoana) | 1-10000 | > 5000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Nako ea ho tsamaisa (matsatsi) | 10 | Ho buisanoa | 15 | 30 | Ho buisanoa | |

Melemo ea li-terminals tsa Copper Tube

1, Lintho tse ntle tsa conductive:

Koporo ke thepa ea boleng bo holimo e nang le thepa e ntle ea conductive, e ka netefatsang phetisetso e tsitsitseng le e sebetsang ea hona joale.

2, Ts'ebetso e ntle ea mocheso:

Koporo e na le conductivity e ntle ea mocheso 'me e ka potlakela ho senya mocheso o hlahisoang ke hona joale, ho thusa ho boloka botsitso le polokeho ea block block.

3, Matla a phahameng le ho hanyetsa kutu:

Li-terminals tsa koporo li na le matla a phahameng le ho hanyetsa kutu, li khona ho mamella meroalo e phahameng le libaka tse fapaneng, 'me ha li khone ho ba le oxidation le corrosion.

4. Khokahano e tsitsitseng:

Li-terminal blocks tsa koporo li sebelisa khokahanyo ea khoele kapa khokahanyo ea plug-in, e ka netefatsang hore khokahanyo ea terata e tiile ebile e ka tšeptjoa, 'me ha e na tloaelo ea ho lokoloha kapa khokahano e mpe.

5, Litlhaloso le mefuta e fapaneng:

Li-terminal blocks tsa koporo li fumaneha ka mefuta le mefuta e fapaneng, e loketseng boholo bo fapaneng ba terata le litlhoko tsa khokahano, 'me e ka fihlela litlhoko tsa maemo a fapaneng a ts'ebeliso.

6, Ho bonolo ho kenya le ho boloka:

Li-terminal blocks tsa koporo li na le moralo o bonolo le o bonolo ho o sebelisa, o etsang hore ho be bonolo ho li kenya le ho li hlokomela. Li loketse ho sebelisoa libakeng tse fapaneng tse kang malapeng, liindasteri le likhoebong.

7.Ka ho toba e fanoa ke moetsi, ka bongata bo boholo, theko e babatsehang, le e feletsenglitlhaloso, ho tšehetsa ho itlhophisa

8. Ho khethoa koporo e khubelu ea boleng bo phahameng e nang le conductivity e ntle, Ho amohela molamu oa koporo oa T2 oa boleng bo phahameng bakeng sa ho hatella, ts'ebetso e tiileng ea annealing, ts'ebetso e ntle ea motlakase, ho hanyetsa hantle ho bola ha electrochemical, le bophelo bo bolelele ba tšebeletso.

9.Acid ho hlatsoa kalafo, ha ho bonolo ho corrode le oxidize

10.Electroplating tikoloho e nang le mocheso o phahameng oa mocheso, e nang le conductivity e phahameng, ho hanyetsa kutu, le ho tšoarella.

Lilemo tse 18+ tsa Copper Tube Terminals Cnc Machining Experience

• Liphihlelo tsa R&D tsa Lilemo tse 18 nakong ea selemo, setempe sa tšepe le likarolo tsa CNC.

• Boenjiniere ba litsebo le botekgeniki ho netefatsa boleng.

•Ho tsamaisoa ka nako

• Boiphihlelo ba lilemo ba ho sebelisana le li-brand tse holimo.

• Mefuta e fapaneng ea mochini oa tlhahlobo le tlhahlobo bakeng sa netefatso ea boleng.

Lisebelisoa

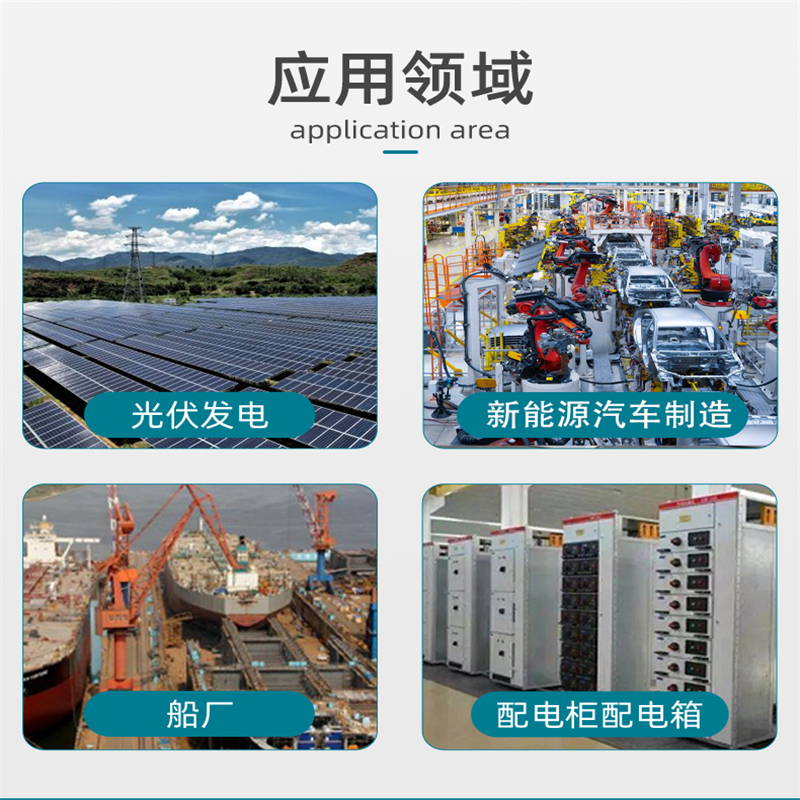

Likoloi tse ncha tsa matla

Phanele ea taolo ea konopo

Kaho ea likepe tsa sekepe

Li-switches tsa matla

Sebaka sa tlhahiso ea matla a photovoltaic

Lebokose la kabo

Likoloi

lisebelisoa tsa lapeng

libapalisoa

li-switches tsa matla

lihlahisoa tsa elektronike

mabone a deske

lebokose la kabo E sebetsa ho

Lithapo tsa motlakase ka lisebelisoa tsa kabo ea matla

Lithapo tsa motlakase le lisebelisoa tsa motlakase

Khokahano bakeng sa

Moetsi oa likarolo tsa lisebelisoa tsa thepa e le 'ngoe

1, Puisano ea bareki:

Utloisisa litlhoko tsa bareki le litlhaloso tsa sehlahisoa.

2. Moralo oa sehlahisoa:

Etsa moralo o ipapisitseng le litlhoko tsa bareki, ho kenyeletsoa lisebelisoa le mekhoa ea tlhahiso.

3, Tlhahiso:

Etsa sehlahisoa u sebelisa mekhoa e nepahetseng ea tšepe e kang ho itšeha, ho cheka, ho sila, joalo-joalo.

4. Kalafo ea holim'a metsi:

Sebelisa lisebelisoa tse nepahetseng tsa bokaholimo joalo ka ho fafatsa, electroplating, kalafo ea mocheso, jj.

5. Taolo ea boleng:

Hlahloba le ho netefatsa hore lihlahisoa li finyella litekanyetso tse boletsoeng.

6, Logistics:

Lokisetsa lipalangoang bakeng sa ho isoa ka nako ho bareki.

7, Ka mor'a ho rekisa tšebeletso:

Fana ka tšehetso le ho rarolla mathata afe kapa afe a bareki.

LBH

A: Re feme.

A: Re na le lilemo tse 20 tsa phihlelo ea tlhahiso ea selemo 'me re ka hlahisa mefuta e mengata ea liliba. E rekisoa ka theko e tlase haholo.

A: Ka kakaretso matsatsi a 5-10 haeba thepa e le teng. Matsatsi a 7-15 haeba thepa e le sieo, ka bongata.

A: E, haeba re na le lisampole setokong, re ka fana ka mehlala. Litefiso tse amanang le tsona li tla tlaleheloa uena.

A: Ka mor'a hore theko e netefatsoe, u ka kopa lisampole ho hlahloba boleng ba lihlahisoa tsa rona. Haeba u hloka feela sampuli e se nang letho ho hlahloba moralo le boleng. Ha feela o ntse o ka khona ho reka thepa e potlakileng, re tla u fa lisampole mahala.

A: Re atisa ho qotsa pele ho lihora tse 24 ka mor'a ho fumana potso ea hau. Haeba u potlakile ho fumana theko, ka kopo, re tsebise lengolo-tsoibila la hau hore re tle re etelletse pele potso ea hau.

A: E itšetlehile ka bongata ba taelo le ha u beha taelo.