Bare ea aluminium e tsamaisang busbar

Lisebelisoa tsa lihlahisoa tsa Copper Tube Terminals

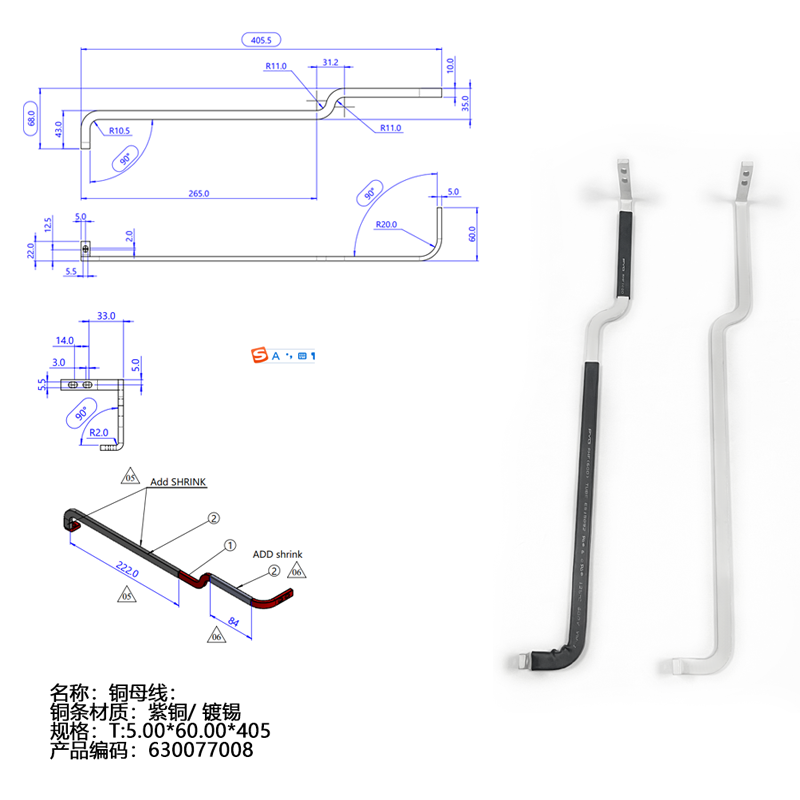

| Sebaka sa Tšimoloho: | Guangdong, China | Mmala: | silevera | |||

| Lebitso la Brand: | haocheng | Boitsebiso: | Koporo | |||

| Nomoro ea Mohlala: | e etselitsoe uena | Kopo: | Copper busbar bakeng sa khokahano ea bese ea DC | |||

| Mofuta: | Letoto la Copper Bar | Sephutheloana: | Mabokose a Tloaelehileng | |||

| Lebitso la sehlahisoa: | Copper busbar bakeng sa khokahano ea bese ea DC | MOQ: | 10 li-PC | |||

| Phekolo ea sefahleho: | customisable | Ho paka: | 10 li-PC | |||

| Sebaka sa marang-rang: | customisable | Boholo: | e etselitsoe uena | |||

| Nako ea ho etella pele: Nako ea nako ho tloha ha odara e beoa ho isa ho e rometsoeng | Bongata (likotoana) | 1-10 | > 5000 | 100-500 | 500-1000 | > 1000 |

| Nako ea ho tsamaisa (matsatsi) | 10 | Ho buisanoa | 15 | 30 | Ho buisanoa | |

Melemo ea li-terminals tsa Copper Tube

Melemo ea ts'ebetso

Litšobotsi tsa li-bars tsa koporo tsa libese tsa DC

1. Thepa:

Conductivity: Koporo e na le motlakase o motle ho feta aluminium, e ka fokotsang tahlehelo ea matla ka katleho 'me e loketse likopo tse phahameng tsa hona joale.

Corrosion Resistance: Koporo e na le khanyetso e ntle ea kutu sebakeng se nepahetseng, empa e ka hloka tšireletso e eketsehileng libakeng tse mongobo kapa tse senyang.

Matla: Koporo e na le matla a phahameng a mochini mme e khona ho mamella khatello e kholo ea mochini.

2. Moralo le Tlhophiso:

Sebopeho: Mehala ea koporo e ka ba e bataletseng, e chitja kapa e khutlonnetsepa, ho latela litlhoko tsa hajoale le sebaka sa ho kenya.

Sizing: Boholo ba mekoallo ea koporo bo khethoa ho ipapisitsoe le matla a hajoale a ho jara le moralo oa sistimi.

INSUlation: Le hoja koporo ka boeona e sebetsa, ho ka 'na ha hlokahala hore ho kenya letsoho lits'ebetsong tse ling ho thibela li-circuits le ho kopana ka phoso.

3. Libaka tsa kopo:

Sistimi ea matla ea DC: e sebelisoa haholo lits'ebetsong tsa polokelo ea matla a betri, li-converter tsa DC, likoloi tsa motlakase le likarolo tse ling.

Lisebelisoa tsa Indasteri: E sebelisetsoa ho fana ka matla a DC ho li-motor tse kholo le lisebelisoa tse ling tsa matla a phahameng.

Matla a Tsosolositsoeng: Ka mokhoa oa ho hlahisa matla a letsatsi, li-module tsa photovoltaic le li-inverters li hokahane.

4. Melemo:

High conductivity: Koporo e na le conductivity e phahameng 'me e ka fokotsa tahlehelo ea matla ka katleho.

Good Thermal Conductivity: Koporo e senya mocheso ka potlako, e fokotsa kotsi ea ho chesa haholo.

Ho tšoarella: Mela ea koporo e na le nako e telele ea tšebeletso 'me e loketse ts'ebetso ea nako e telele ea tsamaiso ea matla.

5. Lintlha:

Boima: Boima ba koporo bo batla bo phahame, kahoo matla a mohaho o tšehetsang o lokela ho nkoa nakong ea ho kenya.

Litšenyehelo: Theko ea koporo hangata e phahame ho feta ea aluminium, kahoo khetho e lokela ho itšetleha ka tekanyetso ea hau.

6. Kemiso le Tlhokomelo:

KHOkahanyo: Etsa bonnete ba hore khokahano e bolokehile, u sebelisa likhokahano tse nepahetseng le li-clamp.

Tlhahlobo e Tloaelehileng: Kamehla hlahloba ho apara, ho senya le ho hanyetsa ho kopana ha mekoallo ea koporo ho netefatsa polokeho le botšepehi ba tsamaiso.

Lilemo tse 18+ tsa Copper Tube Terminals Cnc Machining Experience

• Liphihlelo tsa R&D tsa Lilemo tse 18 nakong ea selemo, setempe sa tšepe le likarolo tsa CNC.

• Boenjiniere ba litsebo le botekgeniki ho netefatsa boleng.

• Ho tsamaisoa ka nako

• Boiphihlelo ba lilemo tsa ho sebelisana le lihlahisoa tse holimo.

• Mefuta e fapaneng ea mochini oa tlhahlobo le tlhahlobo bakeng sa netefatso ea boleng.

Lisebelisoa

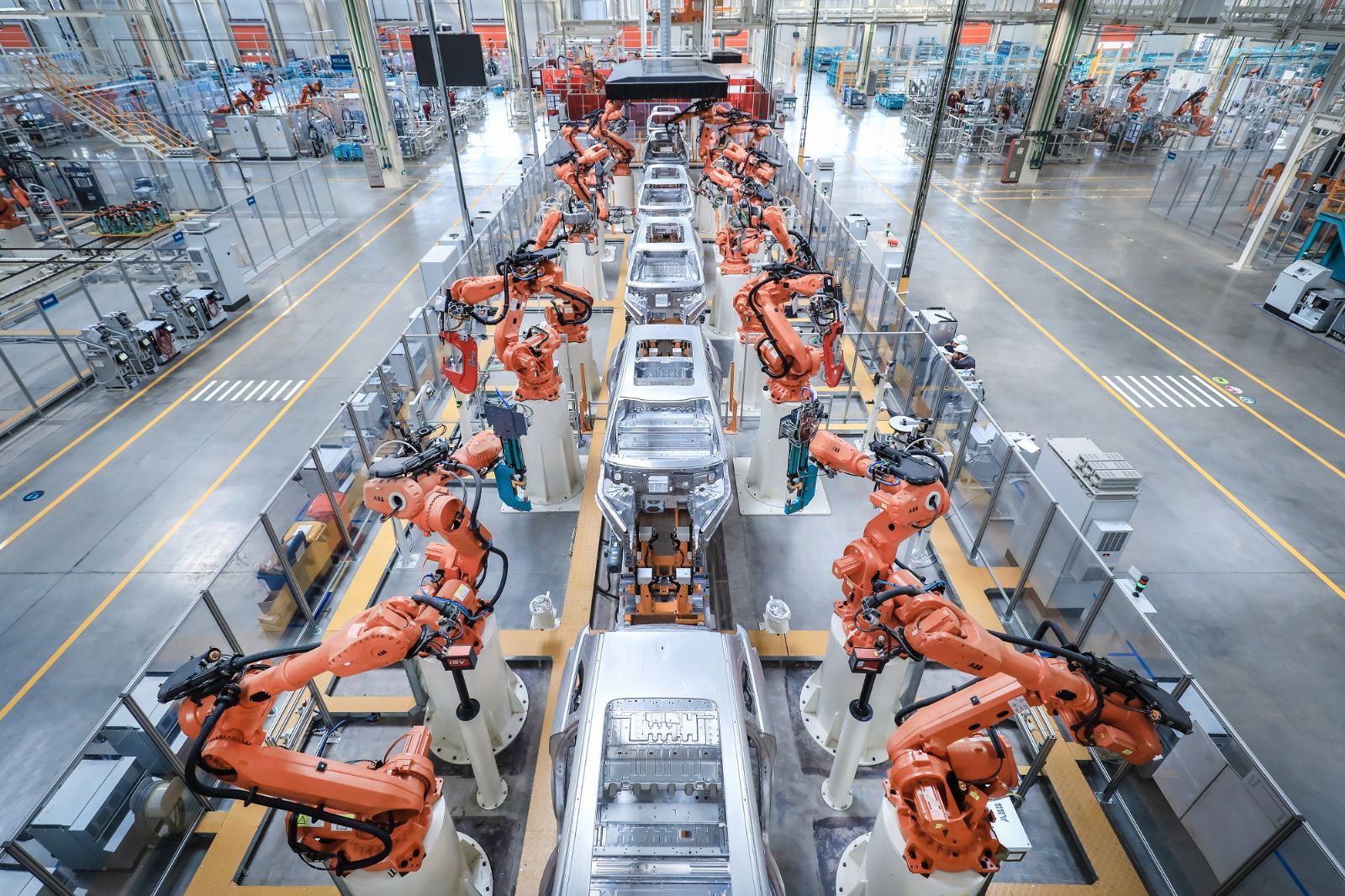

Likoloi tse ncha tsa matla

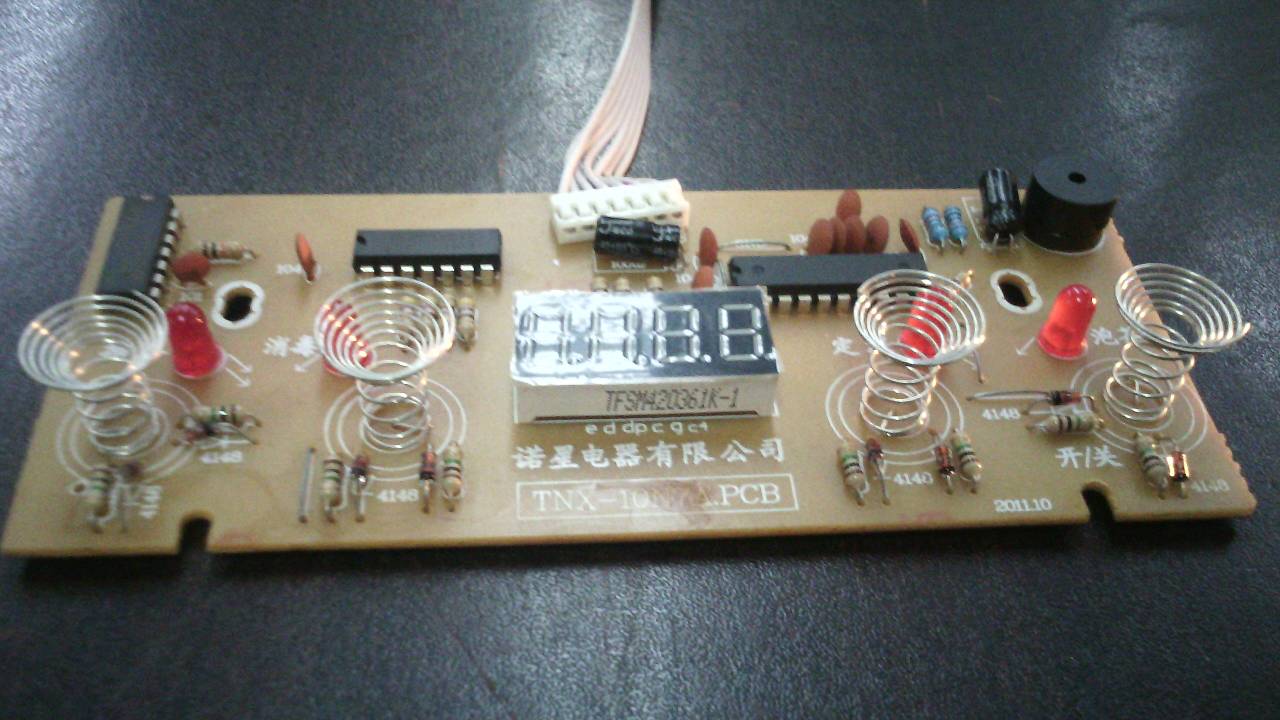

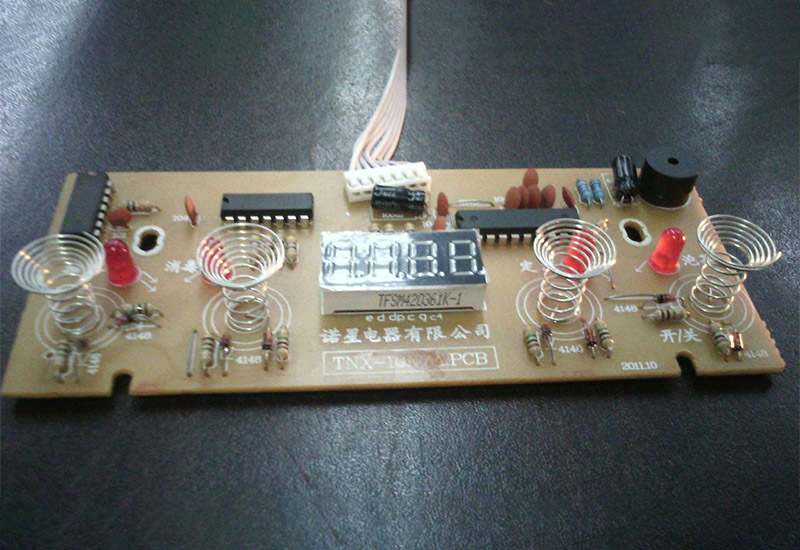

Phanele ea taolo ea konopo

Kaho ea likepe tsa sekepe

Li-switches tsa matla

Sebaka sa tlhahiso ea matla a photovoltaic

Lebokose la kabo

Moetsi oa likarolo tsa lisebelisoa tsa thepa e le 'ngoe

Puisano ya Bareki

Utloisisa litlhoko tsa bareki le litlhaloso tsa sehlahisoa.

Moqapi oa Sehlahisoa

Etsa moralo o ipapisitseng le litlhoko tsa bareki, ho kenyeletsoa lisebelisoa le mekhoa ea tlhahiso.

Tlhahiso

Etsa sehlahisoa u sebelisa mekhoa e nepahetseng ea tšepe e kang ho itšeha, ho cheka, ho sila, joalo-joalo.

Kalafo ea Bokaholimo

Sebelisa lisebelisoa tse nepahetseng tsa bokaholimo joalo ka ho fafatsa, electroplating, kalafo ea mocheso, jj.

Taolo ea Boleng

Hlahloba le ho netefatsa hore lihlahisoa li finyella litekanyetso tse boletsoeng.

Lisebelisoa

Lokisetsa lipalangoang bakeng sa ho isoa ka nako ho bareki.

Tšebeletso ea ka mor'a thekiso

Fana ka tšehetso le ho rarolla mathata afe kapa afe a bareki.

LBH

A: E itšetlehile ka bongata ba taelo le ha u beha taelo.

A: Ka mor'a hore theko e netefatsoe, u ka kopa lisampole ho hlahloba boleng ba lihlahisoa tsa rona. Haeba u hloka feela sampuli e se nang letho ho hlahloba moralo le boleng. Ha feela o ntse o ka khona ho reka thepa e potlakileng, re tla u fa lisampole mahala.

A: Ka kakaretso matsatsi a 5-10 haeba thepa e le teng. Matsatsi a 7-15 haeba thepa e le sieo, ka bongata.

A: Re feme.

A: Re na le lilemo tse 20 tsa phihlelo ea tlhahiso ea selemo 'me re ka hlahisa mefuta e mengata ea liliba. E rekisoa ka theko e tlase haholo.

A: E, haeba re na le lisampole setokong, re ka fana ka mehlala. Litefiso tse amanang le tsona li tla tlaleheloa uena.

A: Re atisa ho qotsa pele ho lihora tse 24 ka mor'a ho fumana potso ea hau. Haeba u potlakile ho fumana theko, ka kopo, re tsebise lengolo-tsoibila la hau hore re tle re etelletse pele potso ea hau.