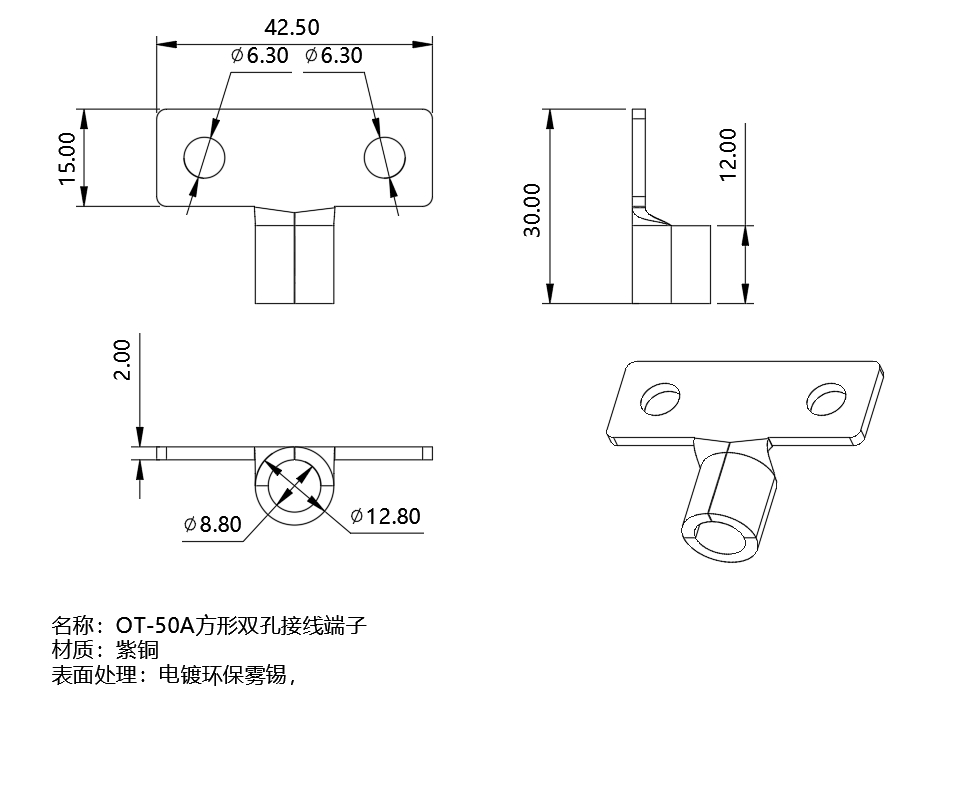

Square double hole terminal block

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | silver | |||

| Brand Name: | haocheng | Material: | Copper | |||

| Model Number: | custom made | Application: | Customized Series | |||

| Type: | Customized Series | Package: | Standard Cartons | |||

| Product name: | Square double hole terminal block | MOQ: | 1000 PCS | |||

| Surface treatment: | 1.5mm²--300mm² | Packing: | 1000PCS | |||

| Wire range: | customizable | Size: | custom made | |||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10 | > 5000 | 100-500 | 500-1000 | > 1000 |

| Lead time (days) | 10 | To be negotiated | 15 | 30 | To be negotiated | |

Advantages of Copper Tube Terminals

Performance advantages

Functions

Conducting Electricity: Facilitate the flow of electrical current between different electrical components or circuits.

Connection Stabilization: Provide a stable and secure connection point, reducing the risk of loose connections that can lead to electrical failures.

Distribution and Branching: Allow for the distribution of power or signals to multiple destinations.

Isolation and Protection: Can help in isolating different electrical circuits for safety and protection against electrical faults.

Structural Features:

- **Reasonable Design**: The square shape often provides a stable base and easy installation orientation. The double holes offer multiple connection options and can accommodate different wire sizes.

- **Durable Materials**: Typically made of materials like plastic or metal with good insulation properties and mechanical strength to withstand environmental conditions and electrical stresses.

- **Markings and Labels**: May have clear markings and labels for easy identification of connection points and wiring configurations.

**Application Fields**:

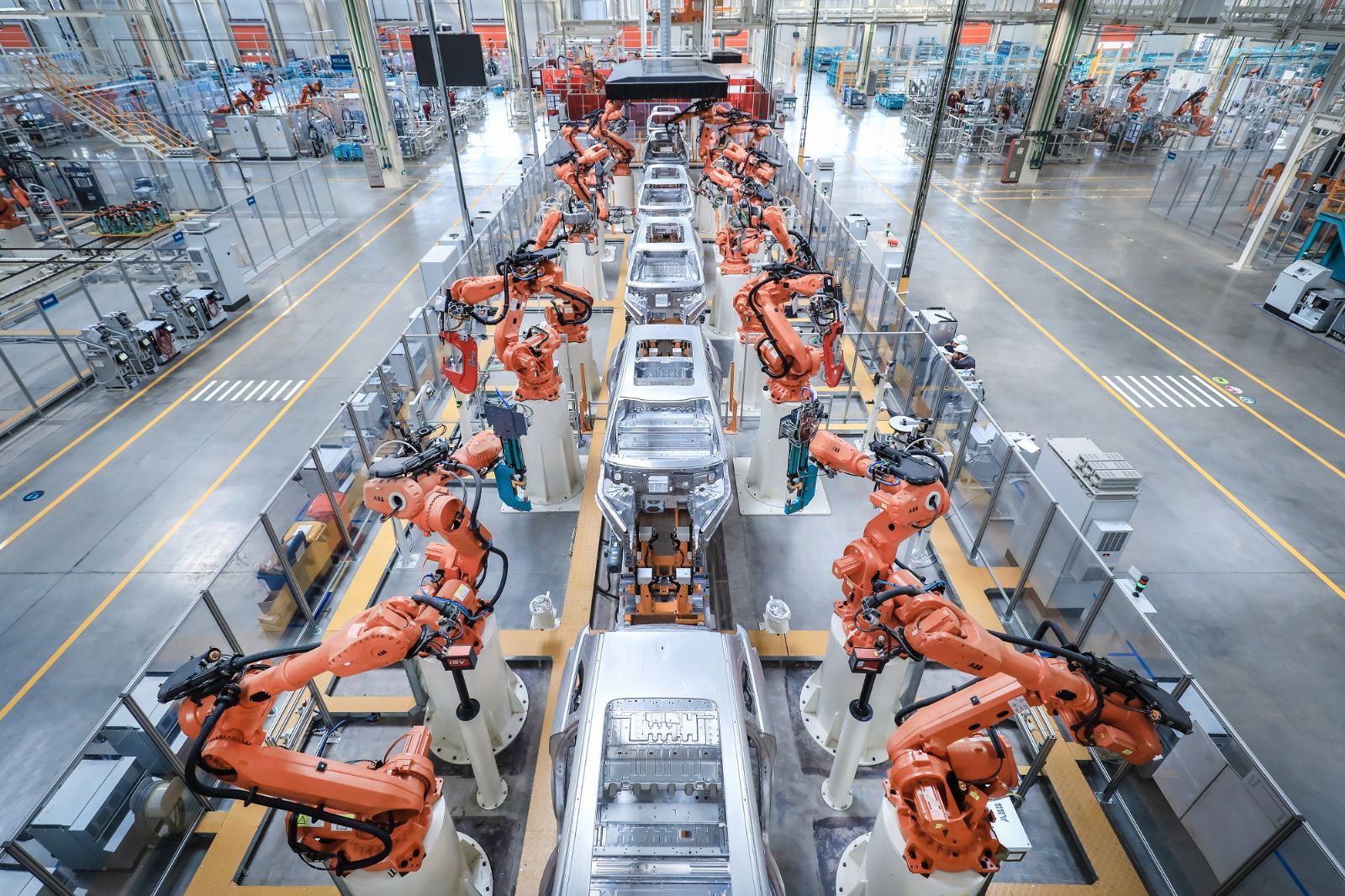

- **Industrial Automation**: Widely used in control panels, machinery, and industrial processes to connect sensors, actuators, and controllers.

- **Building Automation**: In HVAC systems, lighting controls, and security systems for connecting electrical wires.

- **Electrical Power Distribution**: At substations and power distribution centers to connect power cables and electrical equipment.

- **Telecommunications**: For connecting cables in communication equipment and networks.

**Installation Methods**:

- **Screw Termination**: The most common method, where wires are inserted into the holes and secured with screws. This provides a reliable and durable connection.

- **Spring Clamp Termination**: Offers a quicker installation method as wires can be inserted without the need for tools. The spring clamp holds the wire firmly in place.

- **Push-in Termination**: Allows for easy insertion of wires by pushing them into the terminal block. This method is convenient for rapid wiring.

**Manufacturers**:

- **Selection Criteria**: When choosing a manufacturer, consider factors such as product quality, reliability, compliance with standards, customer reviews, and after-sales service.

- **Reputable Brands**: Some well-known manufacturers are known for their high-quality terminal blocks, offering a wide range of products to meet different application requirements.

- **Customization Options**: Some manufacturers may offer customized terminal blocks to meet specific project needs.

To ensure the safe, stable, and reliable operation of the electrical system, it is essential to select the right square double hole terminal blocks based on the following considerations:

- **Electrical Specifications**: Consider the voltage, current, and wire size requirements of the application. Choose terminal blocks that can handle the expected electrical loads.

- **Environmental Conditions**: If the terminal blocks will be exposed to harsh environments such as moisture, dust, or temperature extremes, select models with appropriate protection ratings.

- **Compatibility**: Ensure that the terminal blocks are compatible with the other electrical components and systems being used.

- **Installation Space**: Consider the available space for installation and choose terminal blocks that fit within the given constraints.

- **Cost-Effectiveness**: Balance the cost of the terminal blocks with their quality and performance to ensure a cost-effective solution.

In conclusion, square double hole terminal blocks are essential components in electrical connections. By understanding their functions, features, application fields, installation methods, and choosing the right products and manufacturers, one can ensure the reliable operation of electrical systems.

18+ Years of Copper Tube Terminals Cnc Machining Experience

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

Applications

New energy vehicles

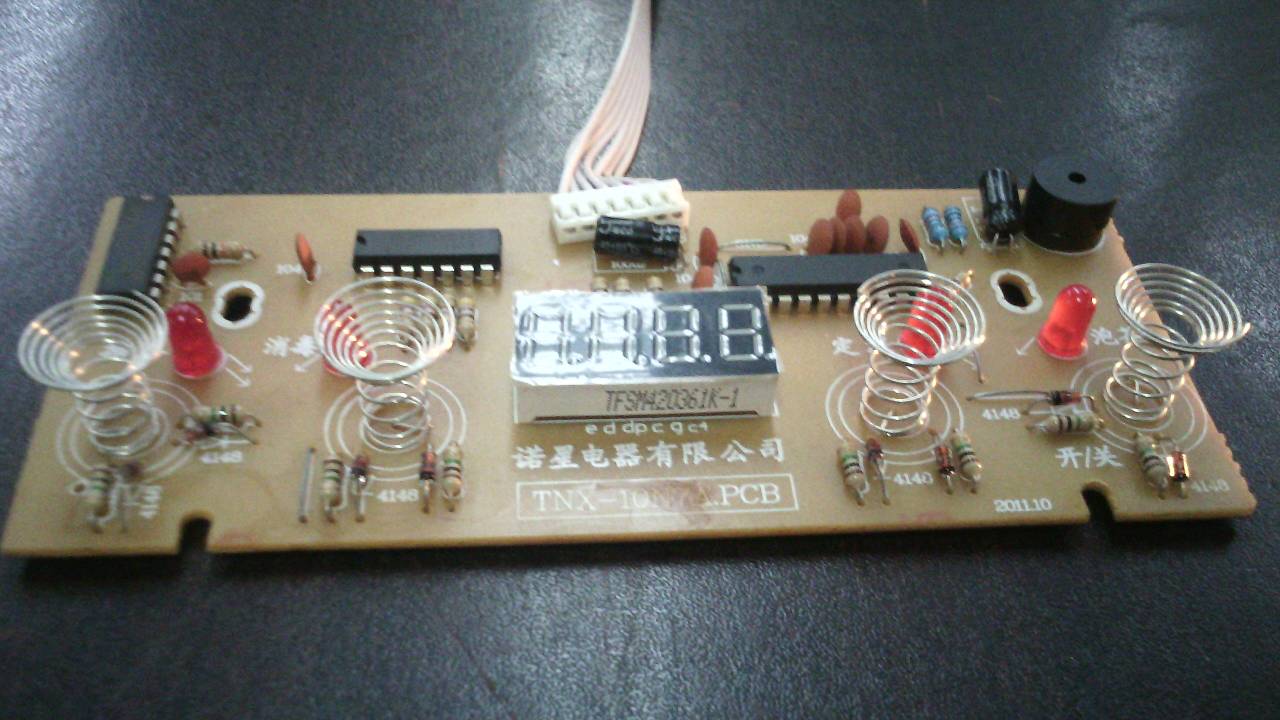

Button control panel

Cruise ship construction

Power switches

Photovoltaic power generation field

Distribution box

One-stop custom hardware parts manufacturer

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

FAQ

A: We are a factory.

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: It depends on the order quantity and when you place the order.

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: It depends on the order quantity and when you place the order.