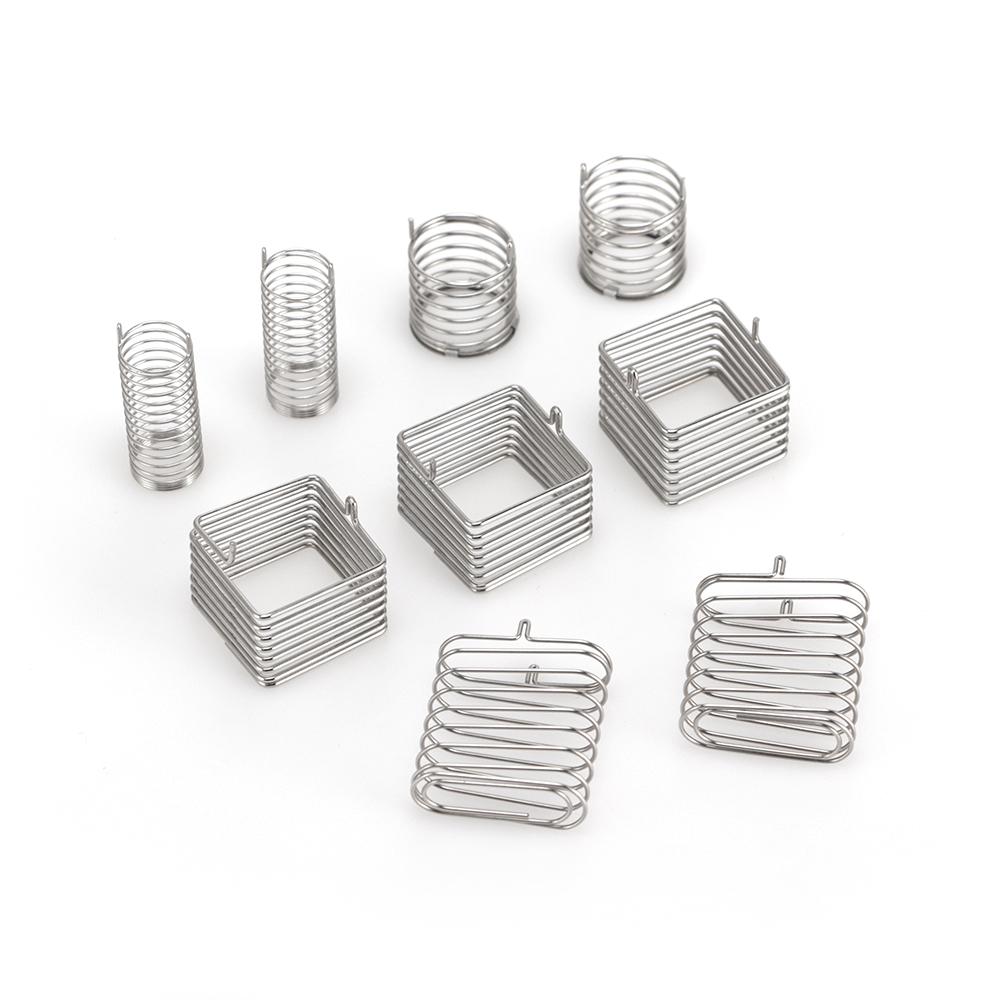

PCB touch button square spring

Application

1. Electronic devices: Used in touch buttons of smartphones, tablets, laptops and other devices to provide reliable tactile feedback.

2. Home appliances: In the control panels of home appliances such as microwave ovens, washing machines, and air conditioners, ensure the sensitivity and durability of the buttons.

3. Automobiles: Used in the central control panel, audio system and navigation equipment of automobiles to improve the comfort and responsiveness of operation.

4. Industrial equipment: Used in various industrial control panels and machinery equipment to ensure the accuracy and stability of operation.

5. Medical equipment: In the control interface of medical devices, provide a reliable touch experience to ensure safe and accurate operation.

6. Smart home: In the control panel of the smart home system, enhance the user interaction experience and improve the overall product quality.

Production Process

Use brass as raw material for preliminary processing such as cutting and stamping

The brass parts are cleaned by polishing, pickling and other cleaning processes to remove the surface oxide layer and impurities.

The electroplating or immersion plating process is performed to form a uniform tin coating on the surface.

Materials and fields

1.304 stainless steel: has good corrosion resistance and processing properties, suitable for most environments.

2.316 stainless steel: Compared with 304 stainless steel, 316 stainless steel has stronger corrosion resistance and is particularly suitable for humid or chemically corrosive environments.

3. Music wire stainless steel: This material has excellent elasticity and fatigue resistance and is often used in high-performance springs.

4.430 stainless steel: Although it has lower corrosion resistance, it is still used in some cost-sensitive applications.

5. Alloy stainless steel: Some special applications may use stainless steel containing alloy elements such as nickel and chromium to improve specific properties.