pcb brass tinned screw terminals

Core Description

Brass PCB Terminals

PCB Screw Terminals

pcb Terminal

pcb terminal lug

Application

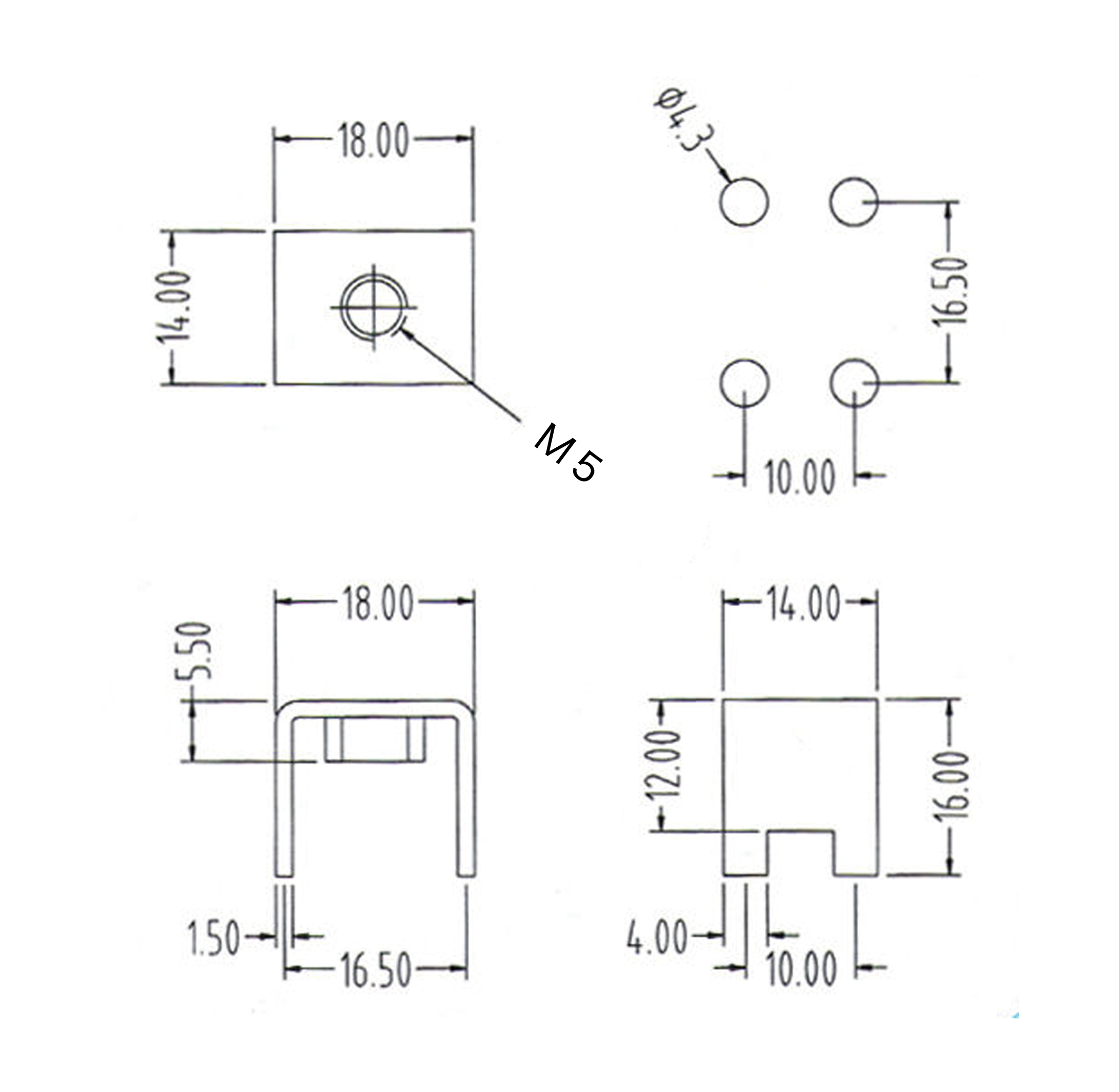

1: Substrate preparation: Use brass as raw material for preliminary processing such as cutting and stamping.

2: Surface treatment: Polish and pickle the brass parts to remove the surface oxide layer and impurities.

Then tin plating is performed to form a uniform tin layer surface.

3: Bolt connection component assembly: Assemble the pre-processed metal parts with plastic shells, bolts and other accessories to form a complete terminal product.

Production Process

Use brass as raw material for preliminary processing such as cutting and stamping

The brass parts are cleaned by polishing, pickling and other cleaning processes to remove the surface oxide layer and impurities.

The electroplating or immersion plating process is performed to form a uniform tin coating on the surface.

Materials and fields

1: Material: brass, copper, stainless steel, etc.

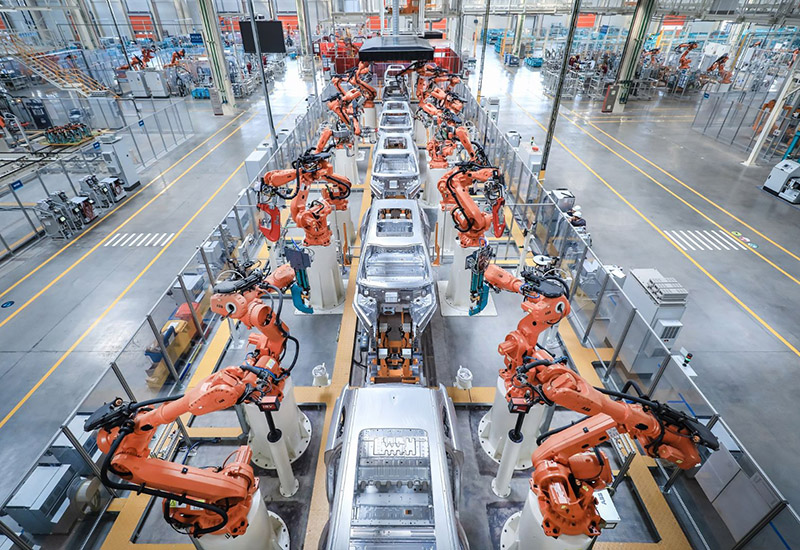

2: This product is used in industrial equipment, instrumentation, transportation equipment, aerospace, power electronics, etc.

Applications

New energy vehicles

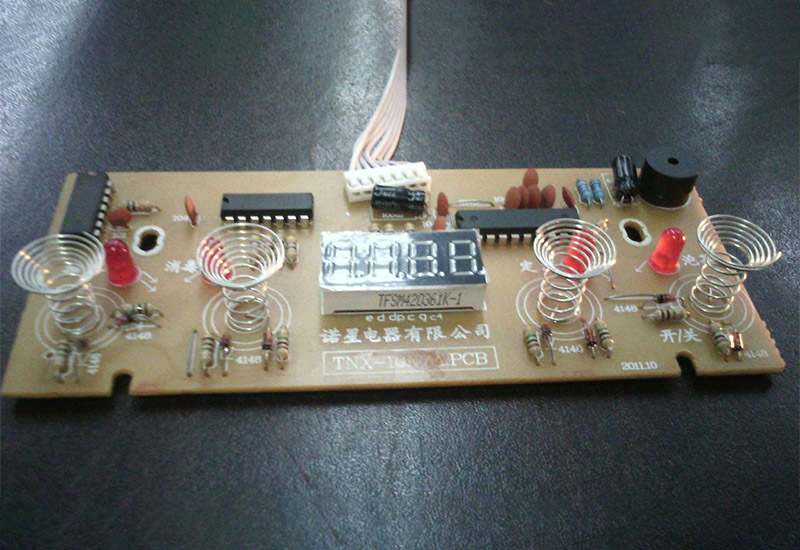

Button control panel

Cruise ship construction

Power switches

Photovoltaic power generation field

Distribution box

Customized service process

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

Corporate advantage

• 18 years of research and development expertise in springs, metal stamping, and CNC parts.

• Proficient and technically skilled engineering to uphold quality standards.

• Reliable on-time delivery.

• Extensive experience collaborating with top brands.

• Diverse array of inspection and testing machinery for quality assurance.

FAQ

A: We are a factory.

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: It depends on the order quantity and when you place the order.