Application of Circular Bare Terminals

A Round Bare Terminal is a common electrical connection component used in scenarios where insulation protection for wire ends is not required. Below are its typical applications and key considerations:

1. Common Application Scenarios

1.Internal Wiring of Electronic Devices

- Used for direct welding or crimping between PCBs and wires (e.g., sensors, relays, or small electronic modules for power/signal connections).

2.Automotive Electrical Systems

- Temporarily connects or repairs automotive wiring harnesses; requires additional insulation (e.g., heat shrink tubing or) to prevent short circuits or wear.

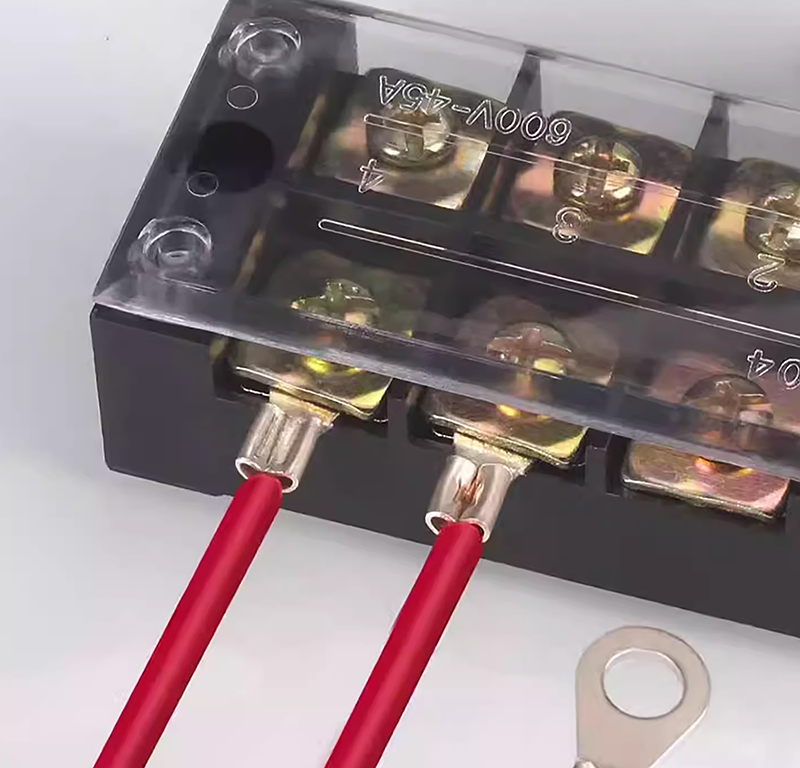

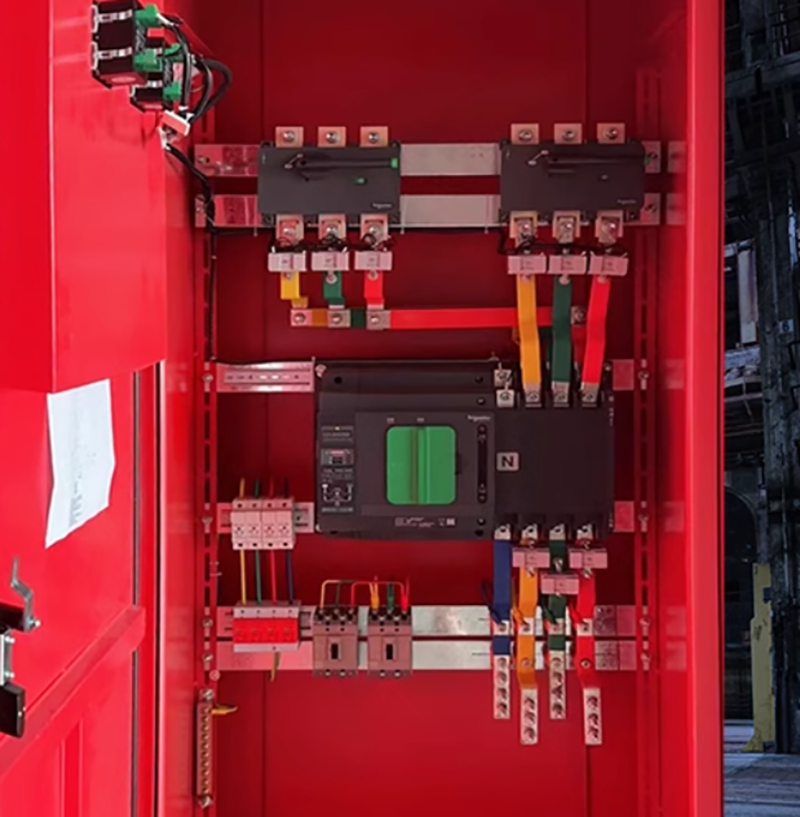

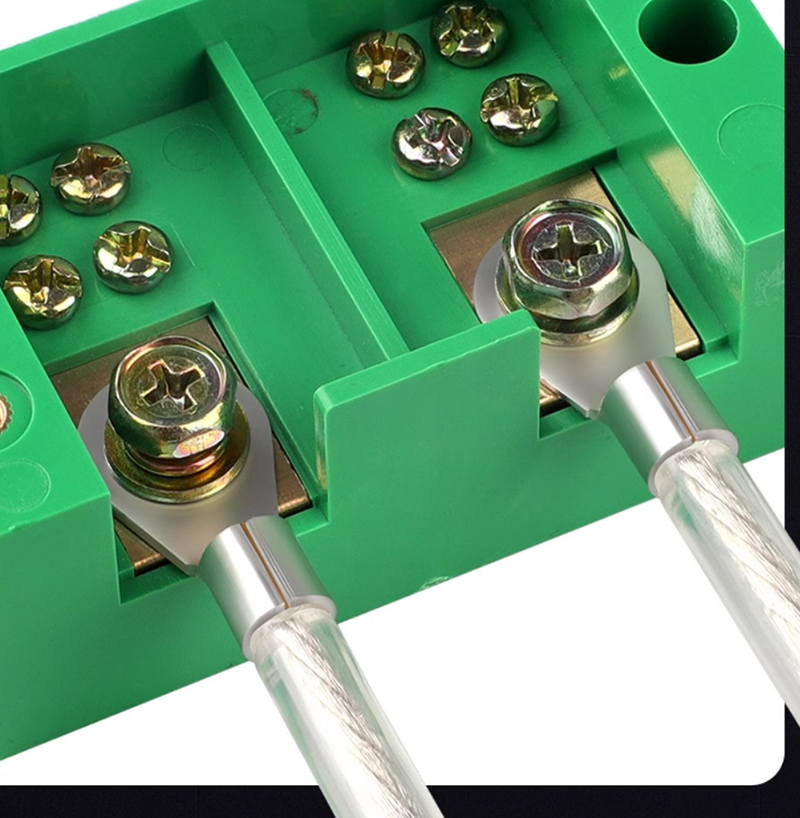

3.Industrial Equipment Wiring

- Connects large-section conductors (e.g., copper bars/aluminum bars) in control cabinets or distribution boxes, commonly used for power input or grounding.

4.Appliance and Lighting Installation

- Internal wiring terminals in lamps, sockets/switches for jumper connections (ensure a dry environment).

5.Testing and Prototyping

Quickly builds temporary circuits or prototypes for flexible adjustments during development.

2. Core Advantages

- Low Cost: No insulation materials simplify manufacturing.

- High Conductivity: Direct metal exposure reduces contact resistance.

- Compatibility: Suitable for various wire gauges (matching terminal specifications), supports welding, crimping, or screw fixation.

3. Key Considerations

1.Safety Protection

- Ensure exposed parts do not accidentally contact other conductors. Use insulation tape, heat shrink tubing, or terminal guards as needed.

2.Environmental Adaptability

- Avoid use in humid, dusty, or corrosive environments to prevent short circuits or oxidation.

3.Electrical Standards

- Comply with local safety standards (e.g., UL, IEC). For high-current applications, copper alloy terminals may be recommended to minimize temperature rise.

4.Alternative Solutions Comparison

|

Type |

Round Bare Terminal |

Round Bare Terminal |

Crimp Terminal |

|

Application |

Internal wiring, temporary connections |

Insulated environments required |

High-reliability permanent connections |

|

Cost |

Low |

Moderate |

Higher |

|

Maintenance |

Requires additional protection |

Plug-and-play |

Requires crimping tools |

5. Typical Specifications

- Wire Gauge Range: 0.5–6 mm² (dependent on terminal model)

- Materials: Tin-plated copper, pure copper, or stainless steel (for corrosion resistance)

- Connection Methods: Screw compression, spring clamping, or welding

If you need specific selection advice, please provide details such as application environment (voltage level, wire gauge, etc.) for further analysis.

Post time: Feb-27-2025