1. Common Parameter Categories

1.Current Rating

●Examples: 10A, 20A, 30A, 50A, 100A, etc. (Must match load requirements with a 10%~20% margin).

2.Conductor Cross-Section

●Conductor Size Range: e.g., 0.5–6mm², 1–10mm², 4–25mm² (Verify compatibility with copper/aluminum wires).

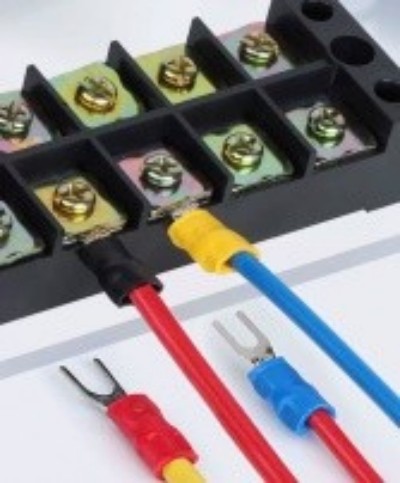

3.Terminal Type

●Plug-and-Socket Design (e.g., Fork Terminal Plug & Socket)

●Screw Clamp Type (e.g., Screw Clamp Terminal)

●Double Fork Splitter Configuration (e.g., Double Fork Splitter Terminal)

4.Protection Rating

●IP Rating: e.g., IP20 (dry environments), IP67 (waterproof/dustproof).

5.Material and Certification

●Materials: Flame-retardant materials such as PA (Polyamide), PBT (Polybutylene Terephthalate).

●Certifications: UL/CUL, IEC 60947, CCC (China Compulsory Certification), etc.

2. Typical Model Examples

|

Model |

Key Specifications |

Application Scenarios |

|

FT-10-6/25 |

10A, 6–25mm² conductors, plug-and-socket type |

Distribution cabinets, industrial equipment |

|

FK-30-4/10 |

30A, 4–10mm² conductors, screw clamp type |

Building distribution boxes, solar inverters |

|

DF-50-2/6 |

50A, 2–6mm² conductors, double fork splitter |

Energy storage systems, marine electronics |

|

EX-20-1/4 |

20A, 1–4mm² conductors, IP67 protection |

Humid/dusty environments (e.g., subway systems) |

3. Selection Guidelines

1.Current and Load Matching

●Ensure the rated current ≥ actual load current (with 10%~20% margin).

2.Conductor Compatibility

●Verify the conductor diameter fully falls within the terminal’s specified range.

3.Environmental Adaptability

●High-Temperature Environments: Choose heat-resistant materials (e.g., PA66).

●Vibration-Prone Applications: Prioritize screw-clamp or locking mechanisms.

4.Installation Method

●Surface-mount or recessed designs depend on enclosure compatibility (e.g., rail-mounted or embedded interfaces).

4. Notes

●Brand-Specific Naming: Models vary by manufacturer (e.g., Phoenix Contact’s FT Series, Weidmüller’s WAGO Series); consult product catalogs.

●Specialized Standards: For hazardous environments (explosive atmospheres) or rail transit, use certified models (e.g., ATEX explosion-proof certification).

If further details are needed (e.g., specific brand models or technical specs), provide additional context such as application environment, voltage, conductor type, or required certifications!

Post time: Apr-15-2025