1.Classified by Conductor Cross-Section (Common Specifications)

|

Conductor Cross-Section (mm²) |

Applicable Cable Diameter (mm) |

Recommended Applications |

|

0.5–1.5 |

0.28–1.0 |

Microelectronic devices, sensors |

|

2.5–6 |

0.64–1.78 |

Household appliances, small distribution boxes |

|

10–16 |

2.0–4.14 |

Industrial equipment, motor wiring |

|

25–35 |

4.0–5.06 |

High-power distribution, transformer connections |

2.Classified by Interface Type

|

Terminal Type |

Technical Features |

Typical Applications |

|

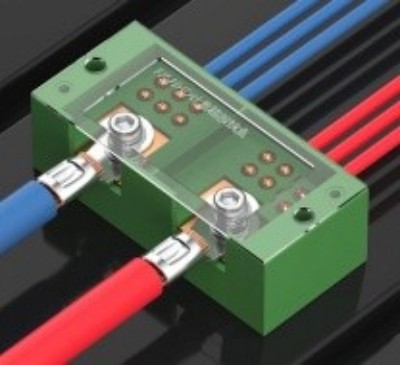

Screw Terminal |

Threaded terminals requiring tightening |

High-reliability scenarios (e.g., power cabinets) |

|

Plug-in Type |

Direct insertion without tools |

Fast maintenance (e.g., PLC wiring) |

|

Multi-Pin Terminal |

Supports parallel connection of multiple wires |

Complex wire harnesses |

3. Classified by

|

Model Suffix |

Protection Features |

Applicable Environments |

|

-IP20 |

Dustproof without insulation sleeve |

Dry indoor environments (e.g., office equipment) |

|

-IP67 |

Waterproof and dustproof, withstands 1m water depth |

Wet/outdoor environments (e.g., ships) |

|

-EX |

Explosion-proof design |

Hazardous locations (e.g., coal mines, petrochemical plants) |

Key Parameters for Selection

1.Conductor Material

●Copper (Cu): High conductivity, ideal for high-current applications (e.g., power distribution systems).

●Aluminum (Al): Lightweight and cost-effective, but avoid direct contact with copper (use transition terminals).

2.Crimping Requirements

●Verify compatibility with mixed copper/aluminum conductors or multi-strand wire connections.

3.Environmental Adaptability

●High-temperature environments (>85°C): Choose heat-resistant materials (e.g., tin-plated copper).

●Vibration-prone scenarios: Prefer terminals with good elasticity (e.g., aluminum alloys).

Typical Brand and Model References

|

Brand |

Model Example |

Core Advantages |

|

Phoenix |

CK 2.5–6 |

High-precision crimping, UL-certified |

|

Molex |

10104–0001 |

Plug-in design for PCB applications |

| Weidmuller |

WAGO 221 Series |

Screw-type terminals for industrial durability |

Important Notes

1.Matching Principles

●Ensure the cross-sectional area is ≥ the cable’s actual current-carrying capacity (refer to IEC 60364).

●Control cable diameter deviation within ±5% to avoid loose crimps.

2.Installation Standards

●Perform a tensile test after crimping (standard value: 70%~80% of the conductor’s tensile strength).

●Replace terminals or apply protective coatings if the insulation sleeve is damaged.

Post time: Apr-15-2025