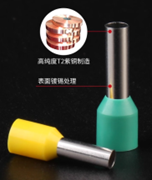

Tube shaped bare end terminal is a type of cold pressed wiring terminal mainly used for connecting and fixing wire ends. It is usually made of copper material, with a surface plated with tin or silver to enhance conductivity and corrosion resistance. Its structure is designed as a tube, which can directly wrap exposed wires and form a stable connection after being fastened with crimping tools. Unlike pre insulated terminals, bare terminals have no insulation material covering the outer layer and need to be used in conjunction with other insulation measures in specific scenarios.

Core functions and application scenarios

·1. Electrical safety

Tube shaped bare ends can crimp multiple wires into a whole, avoiding the risk of short circuits caused by loose copper wires, especially suitable for high-density wiring scenarios (such as automation equipment, power control cabinets)

·2. Conductivity and reliability

Copper material provides excellent conductivity and is suitable for applications that require high current transmission, such as industrial equipment, power systems, and automotive wiring harnesses

·3. Universal adaptation

Different specifications (such as EN4012, EN6012, etc.) can be selected based on the cross-sectional area of the wire to adapt to wires ranging from 0.5mm ² to 50mm ², meeting diverse needs.

Selection and installation points

Specification selection: The model should be matched according to the cross-sectional area and insertion depth of the wire (such as EN series), for example, EN4012 corresponds to a wire cross-sectional area of 4mm ² and an insertion length of 12mm

Crimping process:

Use professional crimping pliers (such as ratchet tools) to ensure a secure crimping;

The stripping length should be precise to ensure that the wire is fully inserted into the end and there is no exposed copper wire

Environmental adaptation: If insulation is required, additional sleeves or pre insulated terminals should be used

Typical product examples

·Using EN4012 tubular bare end as:

Material: T2 purple copper, surface plated with tin/silver;

Applicable wires: 4mm ² cross-sectional area;

·Application:

Industrial control cabinets, power equipment wiring precautions

Before installation, it is necessary to clean the inside of the wires and terminals to avoid foreign objects affecting conductivity;

After crimping, it is necessary to check whether the connection is flat to avoid poor contact;

In humid or dusty environments, it is necessary to use insulation tape or protective covers.

Post time: Mar-01-2025