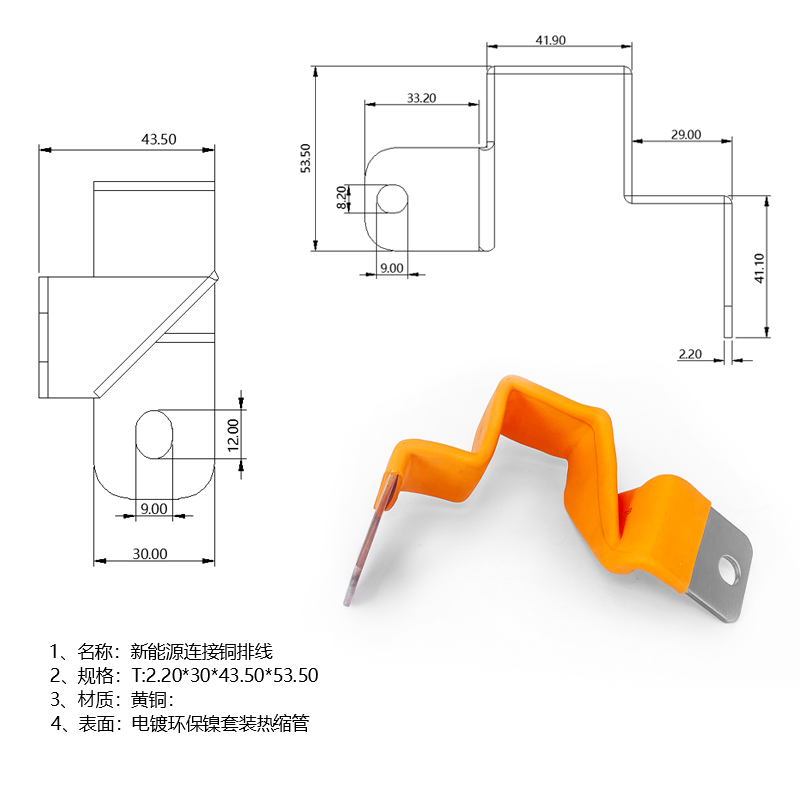

New energy connection softcopper busbar

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | silver | |||

| Brand Name: | haocheng | Material: | Copper | |||

| Model Number: | custom made | Application: | New energy connection soft copper busbar | |||

| Type: | Soft Copper Bar Series | Package: | Standard Cartons | |||

| Product name: | New energy connection soft copper busbar | MOQ: | 10 PCS | |||

| Surface treatment: | customizable | Packing: | 10 PCS | |||

| Wire range: | customizable | Size: | custom made | |||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10 | > 5000 | 100-500 | 500-1000 | > 1000 |

| Lead time (days) | 10 | To be negotiated | 15 | 30 | To be negotiated | |

Advantages of Copper Tube Terminals

Performance advantages

High conductivity: Due to the use of high-purity copper material, the conductivity of the soft copper busbar is very high, which can effectively transmit large currents and reduce energy loss during transmission.

Low inductance: Compared to traditional hard copper bars, the inductance value of the busbar in soft copper bars is lower, which is very advantageous for the transmission of high-frequency currents, can reduce electromagnetic interference, and improve the stability of electrical systems.

Good heat dissipation: The surface area of the soft copper busbar is relatively large, which is conducive to the dissipation of heat. Under high current loads, it can quickly dissipate the generated heat and avoid overheating.

Strong vibration resistance: In some environments with high vibration, such as mechanical equipment, transportation vehicles, etc., the soft nature of the copper busbar enables it to better withstand vibration and impact, is not easily damaged, and ensures the reliability of electrical connections.

Application scenario expansion

In the field of communication, soft copper busbar can be used to connect power equipment, communication equipment, and grounding systems in communication base stations, data centers, and other places, providing stable power supply and good grounding protection for equipment.

Aerospace: Due to its light weight, good flexibility, and high conductivity, soft copper busbar has a wide range of applications in the aerospace field. For example, in the electrical system of an aircraft, it is used to connect various electronic devices and sensors, as well as to transmit power between solar panels and electronic devices on satellites.

Medical equipment: In medical equipment, soft copper busbar can be used to connect high-precision medical instruments and power systems, ensuring stable operation and accurate measurement of the equipment. Meanwhile, its excellent insulation performance can also ensure the safety of patients and medical staff.

Installation and maintenance

The installation of soft copper busbar is very convenient and can be cut and bent according to actual needs. During the installation process, only simple tools are needed to complete the connection, without the need for complex welding or bolt connections. In addition, the maintenance of the soft copper busbar is also very simple, just need to regularly check its connection status and insulation performance, and replace it in a timely manner if there are any problems.

In short, soft copper busbar has become an important product in the field of modern electrical connections due to its excellent performance and wide range of applications. With the continuous advancement of technology and the growing market demand, the application prospects of soft copper busbar will be even broader.

18+ Years of Copper Tube Terminals Cnc Machining Experience

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

Applications

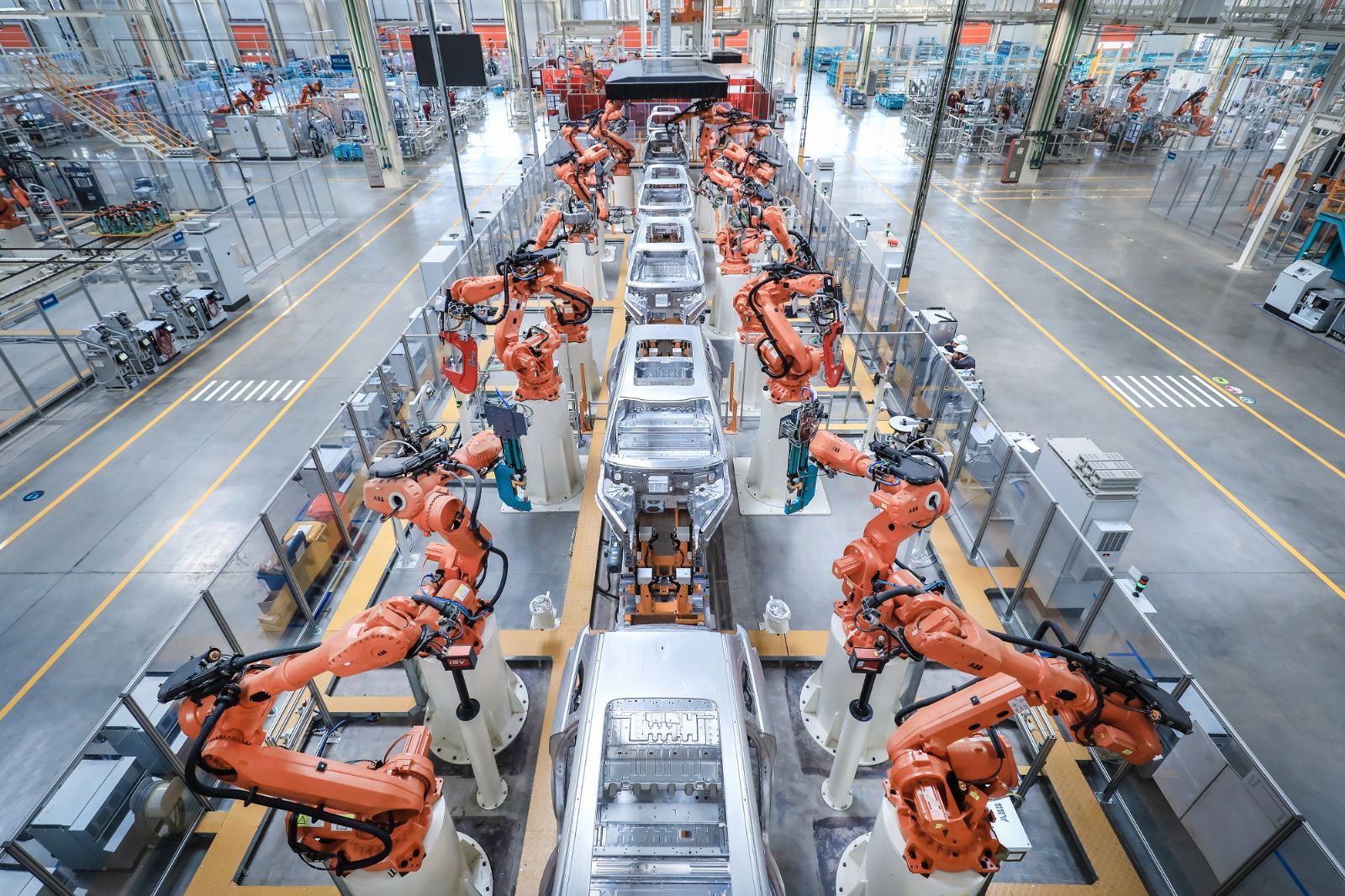

New energy vehicles

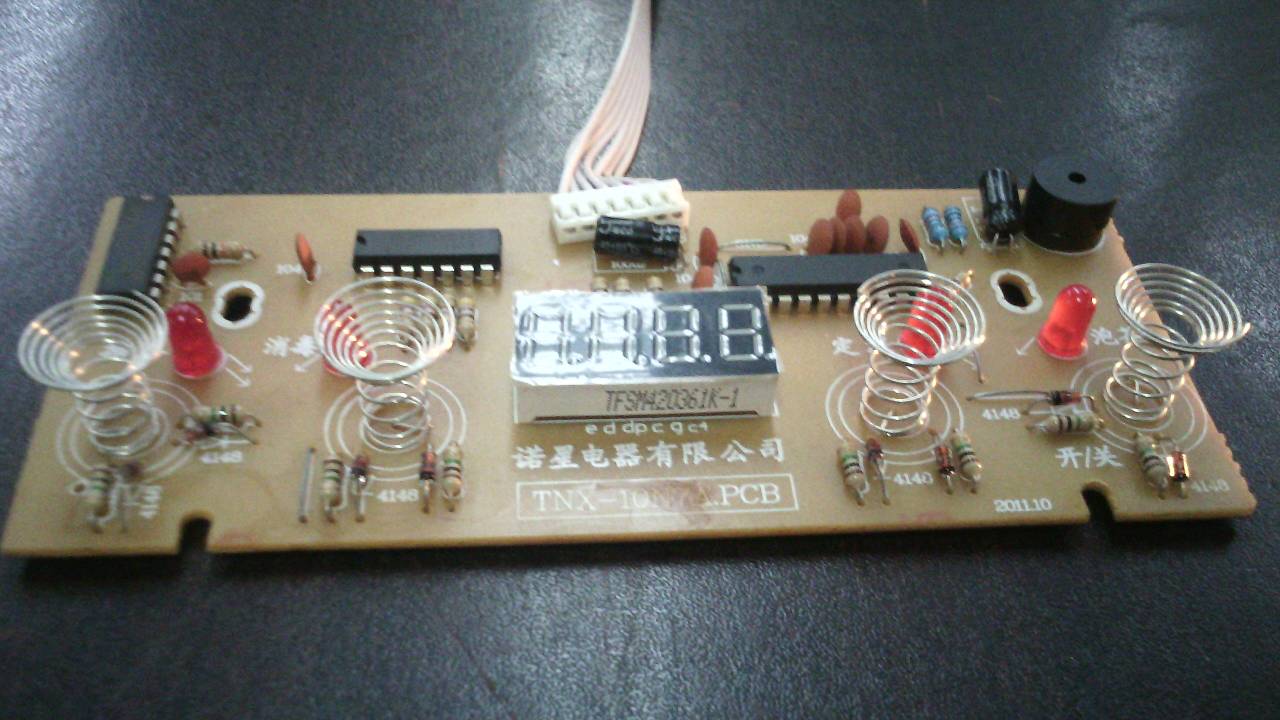

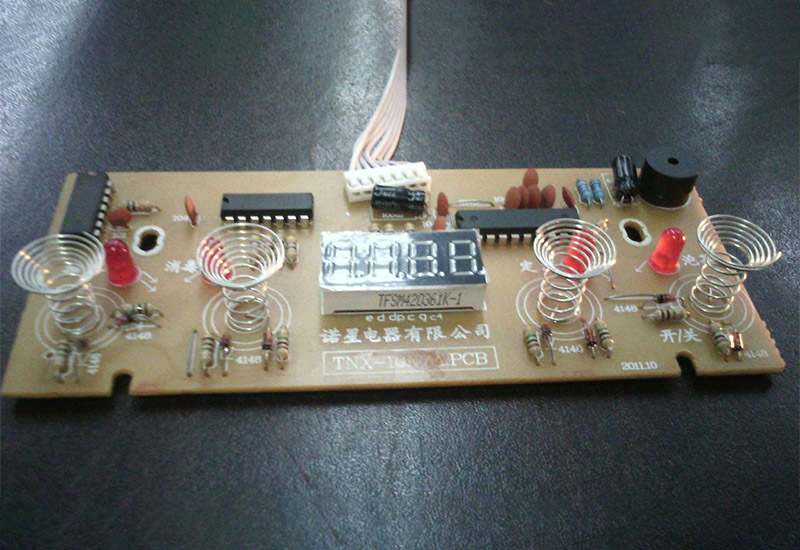

Button control panel

Cruise ship construction

Power switches

Photovoltaic power generation field

Distribution box

One-stop custom hardware parts manufacturer

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

FAQ

A: We are a factory.

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: It depends on the order quantity and when you place the order.