FORK SHAPE PREINSULATION TERMINAL

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | silver | |||

| Brand Name: | haocheng | Material: | customized | |||

| Model Number: | customized | Application: | Bearing axial tensile force |

|||

| Type: | Tension spring | Package: | Standard Cartons | |||

| Product name: | Tension spring | MOQ: | 1000 PCS | |||

| Surface treatment: | customizable | Packing: | 1000 PCS | |||

| Wire range: | customizable | Size: | customized | |||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | > 5000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 10 | To be negotiated | 15 | 30 | To be negotiated | |

Advantages of Copper Tube Terminals

Performance advantages

The work of a tension spring is based on Hooke's law (F=kx). Among them, F is the elastic force generated by the tension spring, k is the stiffness coefficient of the tension spring (which depends on factors such as the material and geometric shape of the spring), and x is the elongation of the tension spring. When an external force stretches a tension spring, the elongation x of the tension spring is proportional to the magnitude of the external force, and the tension spring will generate an elastic force equal in magnitude and opposite in direction to the external force. For example, when you stretch a tension spring with a force of 10N on a tensioner, and the stiffness coefficient of the tension spring is 5N/cm, according to Hooke's law, it can be calculated that the tension spring has extended by 2cm, and the tension spring will generate a 10N elastic force to resist the stretch.

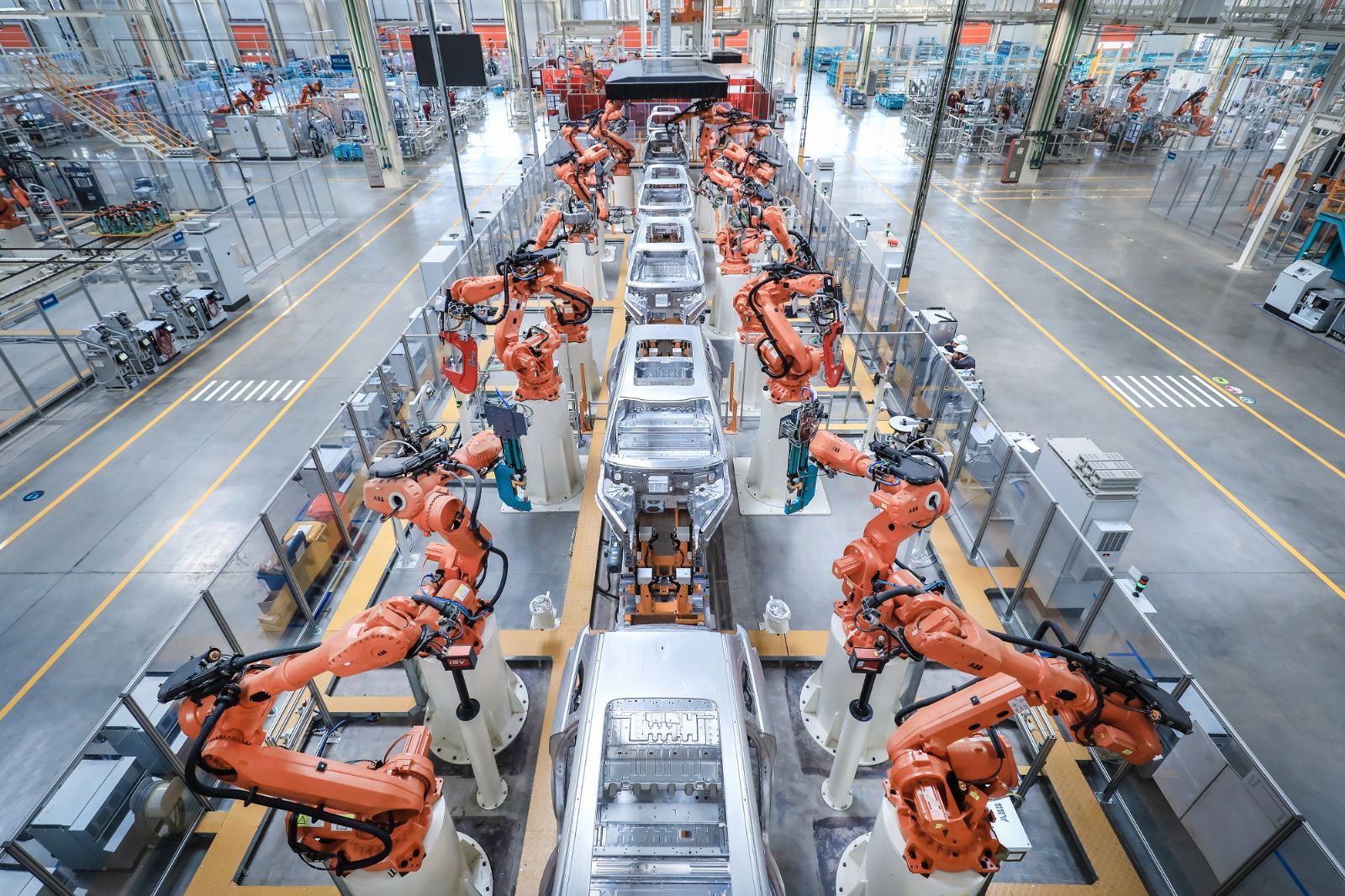

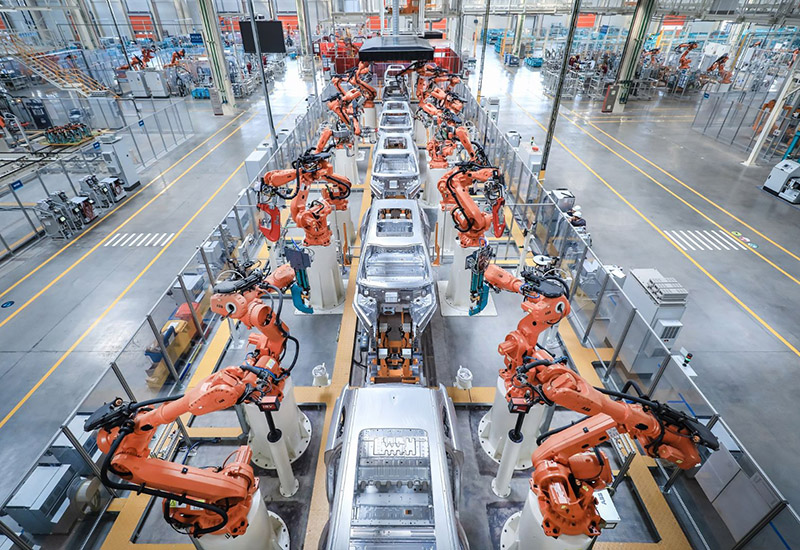

Mechanical manufacturing

On automated production lines, tension springs are used for resetting and tightening various mechanical devices. For example, in some stamping equipment, a tension spring can connect the punch and the body. After the punch completes the stamping action, the tension spring pulls the punch back to its initial position, preparing for the next stamping. At the same time, in some tensioning devices of conveyor belts, tension springs can adjust the tightness of the conveyor belt, ensuring that the conveyor belt can stably transport materials. If the conveyor belt is too loose, the tension spring will automatically tighten to prevent material slippage and other issues during transportation.

automotive industry

There are many components in the engine compartment of a car that use tension springs. For example, the tension spring of the throttle valve can ensure that the throttle valve can quickly return to the closed position after releasing the accelerator pedal, thereby controlling the intake volume of the engine. In the adjustment device of car seats, tension springs also play a role, such as the adjustment of seat backs. Tension springs can assist the backrest in maintaining stability after adjusting the angle and provide tension when it needs to be restored to its initial position.

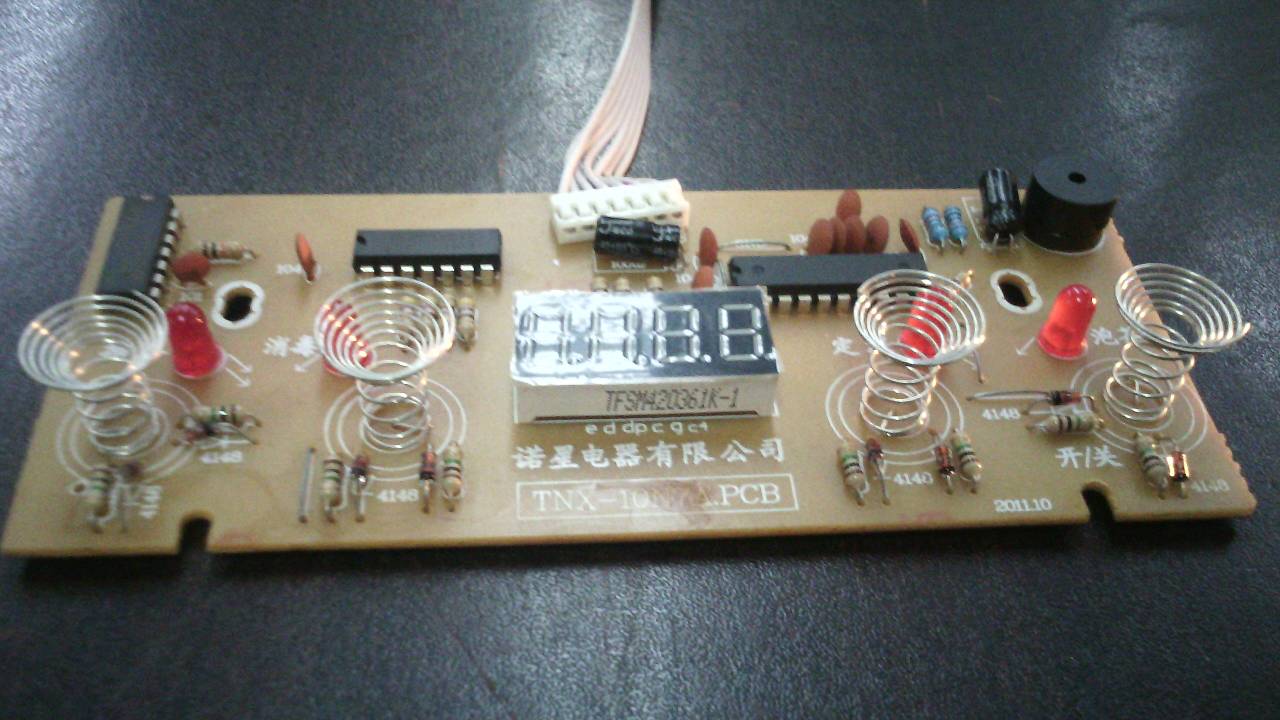

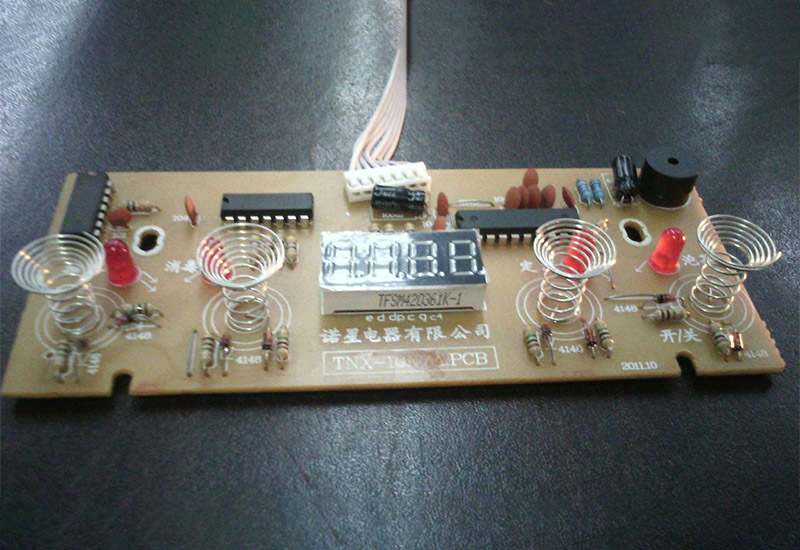

Electronic devices

In the internal structure of some electronic devices, tension springs are used to connect components such as circuit boards and casings. When it is necessary to open the casing of an electronic device for maintenance or replacement of parts, a tension spring can provide a certain degree of elastic connection, making it easy to disassemble and install. Meanwhile, in some small electronic devices such as flip phones (although less commonly used nowadays), tension springs can help the flip to achieve smooth movement during opening and closing, and provide appropriate elasticity to keep the flip open or closed.

18+ Years of Copper Tube Terminals Cnc Machining Experience

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

Applications

New energy vehicles

Button control panel

Cruise ship construction

Power switches

Photovoltaic power generation field

Distribution box

One-stop custom hardware parts manufacturer

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

FAQ

A: We are a factory.

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: It depends on the order quantity and when you place the order.