Fast charging of charging stations with positive and negative copper bars

Product parameters

| Place of Origin: | Guangdong, China | Color: | silver | ||

| Brand Name: | haocheng | Material: | Copper | ||

| Model Number: | 10A-1000A | Application: | Current busbar | ||

| Type: | Copper busbar wire | Package: | Standard Cartons | ||

| Product name: | Positive and negative copper busbar wires |

MOQ: | 100 PCS | ||

| Surface treatment: | customizable | Packing: | 100 PCS | ||

| Wire range: | customizable | Size: | 10-500mm | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 10 | 15 | 30 | To be negotiated | |

Advantages of Copper Tube Terminals

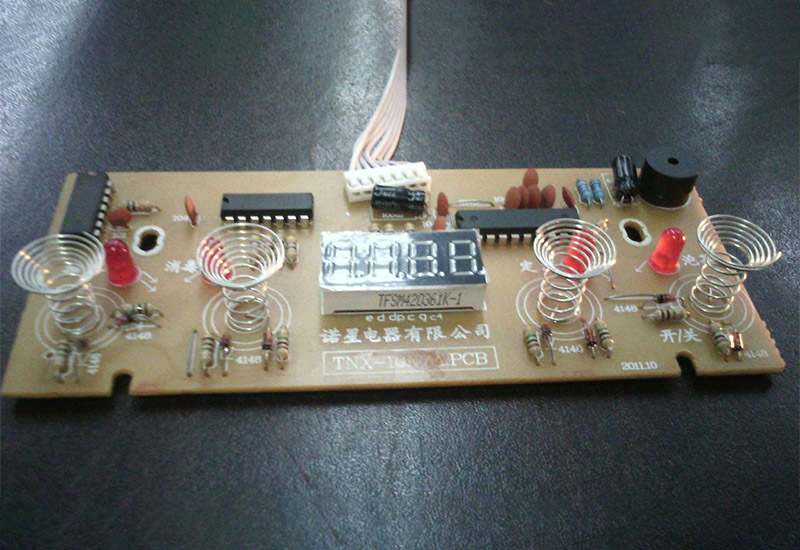

Excellent conductive properties

Made of high-quality pure copper material, it ensures excellent conductivity, effectively reduces transmission loss, and improves charging efficiency.

Good thermal conductivity

The heat generated during the fast charging process needs to be effectively dissipated, and our positive and negative copper busbar design takes into account good thermal conductivity and heat dissipation performance to ensure stable system operation.

High strength and corrosion resistance

The surface has undergone special acid washing and electroplating treatment, which has good corrosion resistance and can adapt to various harsh environmental conditions, ensuring long-term stable use.

Stable connection

Strict production processes and high-precision processing equipment ensure that the positive and negative copper bars can be accurately connected to the charging station system, reducing contact impedance and improving current transmission efficiency.

Various specifications and types

High precision processing equipment and a strong production team ensure the production of different product specifications and various forms of products. Ensure product diversity to meet various customer needs

Easy to install and maintain

The copper terminal blocks have a simple and easy-to-use design, which makes them easy to install and maintain. They are suitable for use in various places such as homes, industries and businesses.

Applications

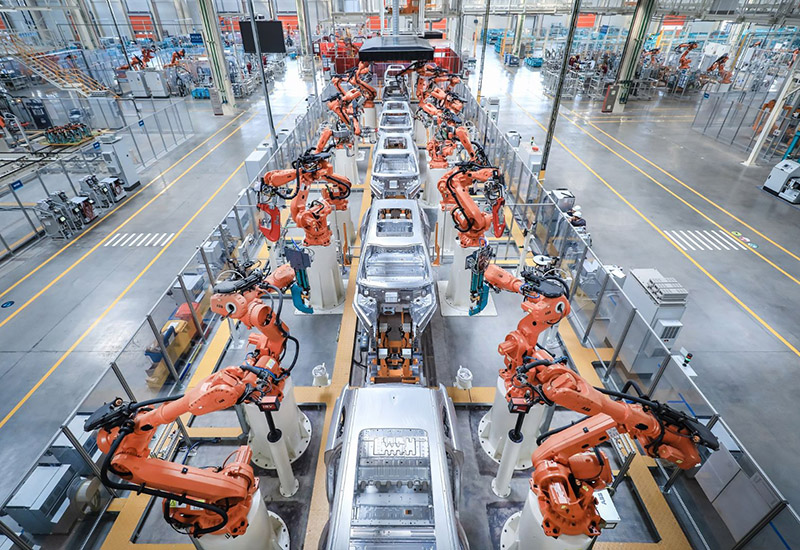

New energy vehicles

Button control panel

Cruise ship construction

Power switches

Photovoltaic power generation field

Distribution box

Customized service process

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

Corporate advantage

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

FAQ

A: We are a factory.

A: It depends on the order quantity and when you place the order.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.