Compression spring

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | silver | |||

| Brand Name: | haocheng | Material: | customized | |||

| Model Number: | customized | Application: | Enduring axial pressure | |||

| Type: | compression spring | Package: | Standard Cartons | |||

| Product name: | compression spring | MOQ: | 1000 PCS | |||

| Surface treatment: | customizable | Packing: | 1000 PCS | |||

| Wire range: | customizable | Size: | customized | |||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | > 5000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 10 | To be negotiated | 15 | 30 | To be negotiated | |

Advantages of Copper Tube Terminals

Performance advantages

Shape and size:Compression springs generally have a cylindrical spiral shape with equal pitch. Its main dimensions include the outer diameter, inner diameter, center diameter (the average of the outer and inner diameters), free height (the height when not subjected to external forces), and the diameter of the spring wire. The design of these sizes depends on the specific application scenario. For example, in small electronic devices, the size of the compression spring may be very small, with an outer diameter of only a few millimeters, while in large industrial machinery shock absorbers, the outer diameter of the compression spring may reach tens of centimeters, and the free height will also be correspondingly high to meet the needs of withstanding high pressure and sufficient compression stroke.

End structure:The end forms of compression springs are diverse, with common ones being ground flat and non ground flat. The flat end compression spring can distribute pressure more evenly and reduce stress concentration when subjected to pressure. In some situations where high stability is required, such as shock absorbers for precision instruments, a flat end compression spring can provide more reliable support. In addition, there are some special end structures, such as tight and flat ends (the spring wires at both ends are tight and flat), which can better adapt to specific installation spaces and stress modes.

Shock absorption and buffering: Pressure springs are widely used for shock absorption and buffering in various mechanical equipment. For example, in punching equipment, a huge impact force is generated when the punch performs a punching action. The pressure spring is installed between the base and worktable of the punch press. During the downward pressure process of the punch press, the spring is compressed, absorbing and buffering some of the impact force, thereby protecting the mechanical structure and mold of the punch press and reducing equipment damage caused by long-term severe impact. Meanwhile, in machine tools such as milling machines and drilling machines, pressure springs are also used to buffer the cutting force between the tool and the workpiece, making the cutting process smoother.

Elastic support: In some mechanical devices that require elastic support, pressure springs play a crucial role. For example, in the support structure of a conveyor, pressure springs can serve as elastic support elements. When the weight of the material on the conveyor changes, the pressure spring can adaptively adjust the support force to ensure that the conveyor runs smoothly under different load conditions. In the worktable support of precision machinery, pressure springs can provide precise elastic support, enabling the worktable to quickly return to its equilibrium position under small external disturbances, ensuring the accuracy of precision machining.

Reset function: Many mechanical moving parts need to be reset after the action is completed, and pressure springs are ideal components for achieving this function. For example, in mechanical fixtures, when the fixture releases the workpiece, the pressure spring can restore the gripper of the fixture to its initial clamping position, preparing for the next clamping operation. In the valve mechanism of automobile engines, pressure springs are used to quickly reset the valves after opening, ensuring the normal intake and exhaust functions of the engine.

18+ Years of Copper Tube Terminals Cnc Machining Experience

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

Applications

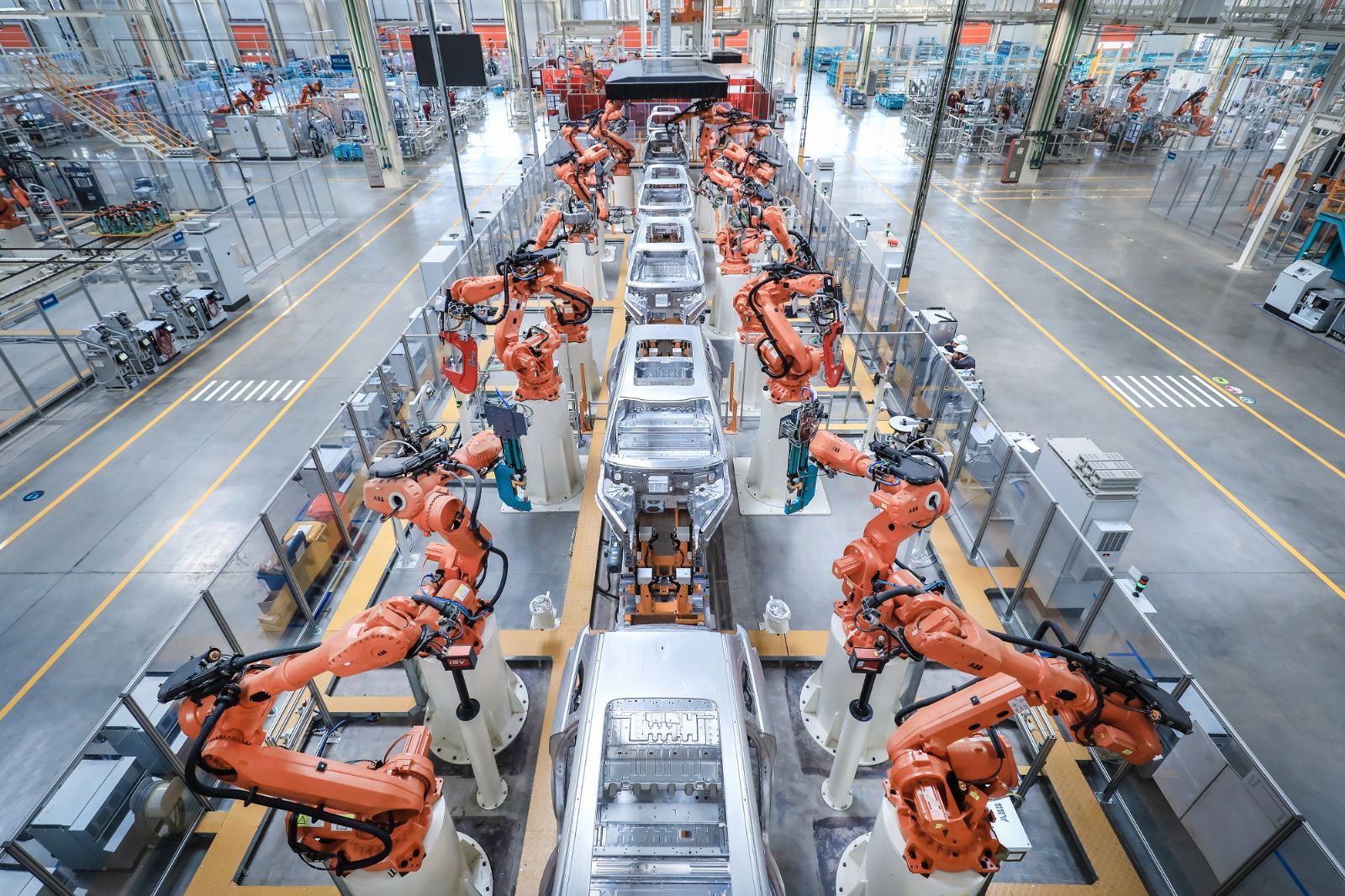

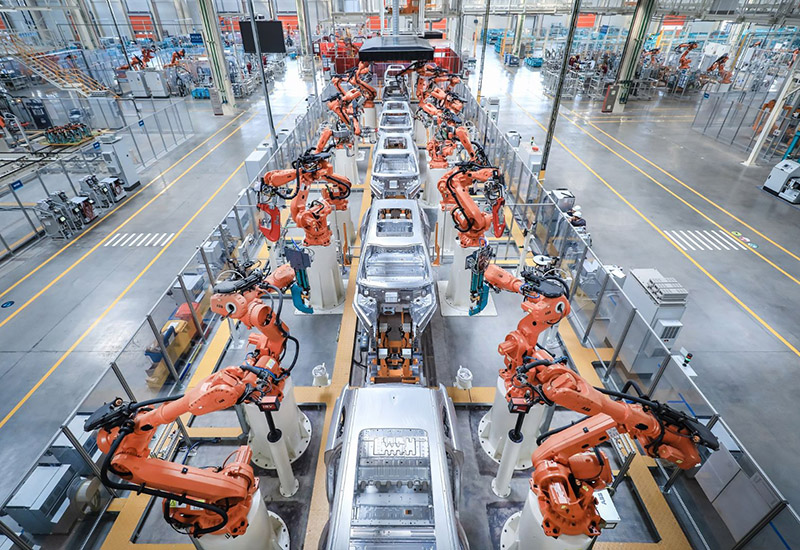

New energy vehicles

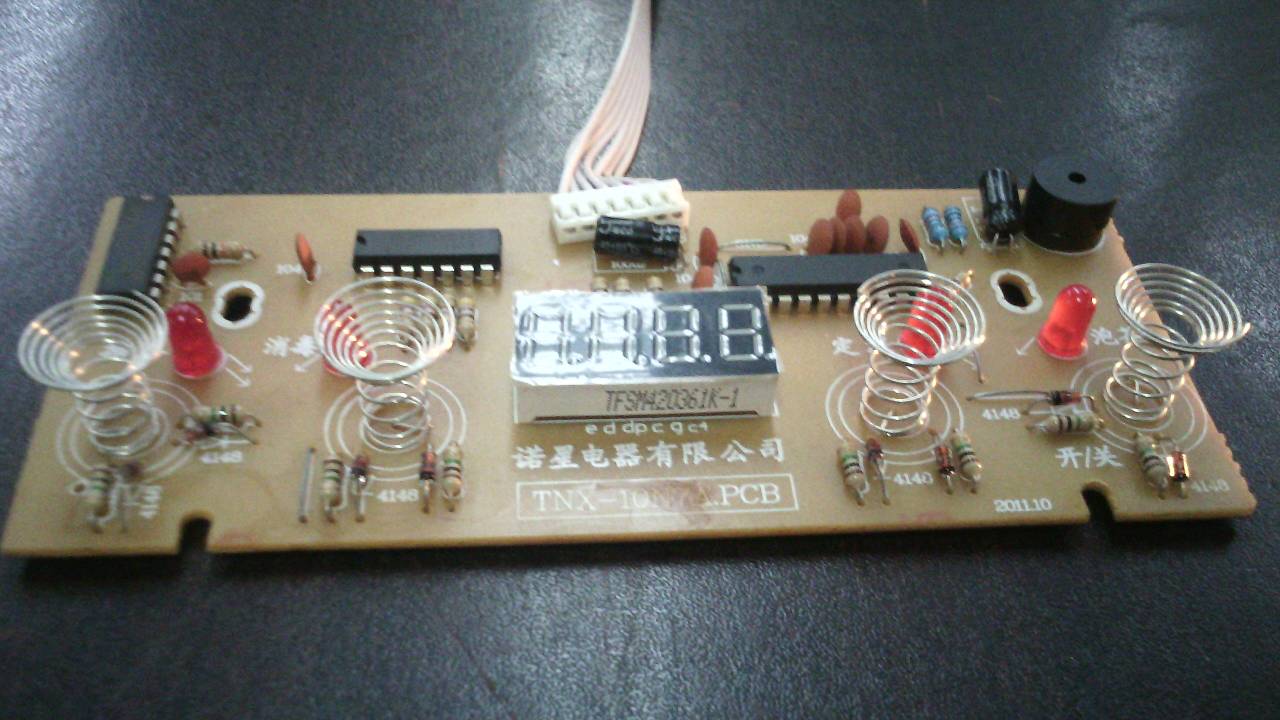

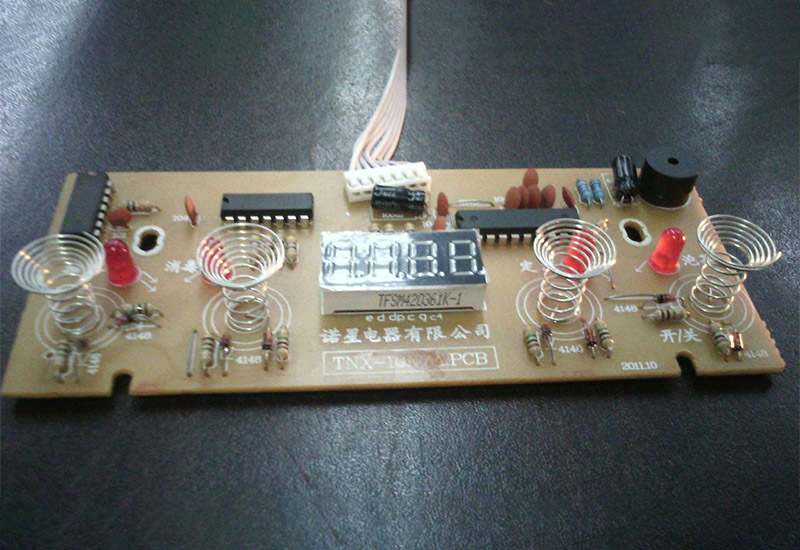

Button control panel

Cruise ship construction

Power switches

Photovoltaic power generation field

Distribution box

One-stop custom hardware parts manufacturer

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

FAQ

A: We are a factory.

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: It depends on the order quantity and when you place the order.