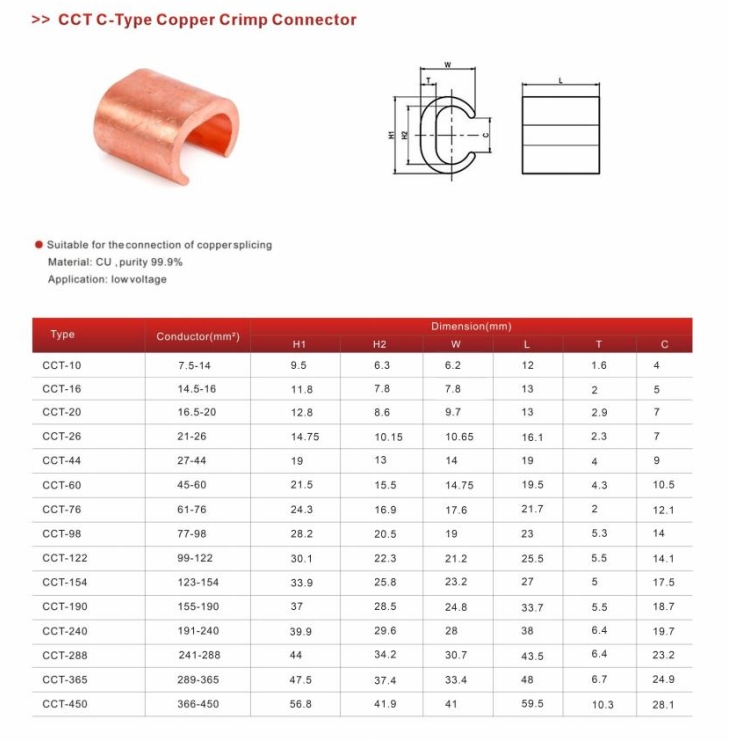

CCT C-Type Copper Crimp Connector

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | silver | |||

| Brand Name: | haocheng | Material: | Copper | |||

| Model Number: | custom made | Application: | CCT C-Type Copper Crimp Connector | |||

| Type: | Copper Bar Series | Package: | Standard Cartons | |||

| Product name: | CCT C-Type Copper Crimp Connector | MOQ: | 100 PCS | |||

| Surface treatment: | customizable | Packing: | 100 PCS | |||

| Wire range: | CCT-10---CCT-450 | Size: | custom made | |||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10 | > 5000 | 1000-5000 | 5000-10000 | > 10000 |

| Lead time (days) | 10 | To be negotiated | 15 | 30 | To be negotiated | |

Advantages of Copper Tube Terminals

Performance advantages

C-type copper crimp connector is a widely used connection device in the field of electrical connections. Here is a brief introduction about it:

1、 Structural characteristics

Main material

The C-type copper crimp connector is mainly made of high-quality copper material. Copper has good conductivity and thermal conductivity, which can ensure stable transmission of current and reduce energy loss. Meanwhile, copper has relatively good corrosion resistance and can be used under different environmental conditions.

Shape design

The "C-type" in its name refers to the connector having a C-shaped appearance. This design enables the connector to easily clamp the wires or cables to be connected during installation, providing stable mechanical connections and electrical contacts.

C-type structures usually have a certain degree of elasticity and can adapt to wires of different diameters, ensuring tight connections.

2、 Working principle

Crimping method

C-type copper crimping connectors are physically connected to wires using crimping tools. During the crimping process, the crimping tool applies pressure to the connector, causing the metal part of the connector to tightly wrap around the wire, forming a secure connection.

The crimping connection has the advantages of reliable connection, low contact resistance, strong resistance to vibration and tension. Compared with traditional welding connection methods, crimping connections do not require the use of heat sources, are easier and faster to operate, and do not produce harmful gases and waste residue, making them more environmentally friendly.

Electrical contact

After the connector is crimped with the wire, the metal part inside the connector is in close contact with the conductor of the wire, achieving electrical connection. Good electrical contact can ensure smooth transmission of current, reduce heating and energy loss caused by contact resistance.

3、 Application Fields

Power industry

In the power transmission and distribution system, C-type copper crimp connectors can be used to connect overhead wires, cable terminals, etc. It can withstand high voltage and current, ensuring the safe and stable operation of the power system.

For example, in the construction and maintenance of substations, C-type copper crimp connectors are widely used in busbar connections, grounding systems, and other parts.

Communication industry

In communication networks, C-type copper crimp connectors can be used to connect communication cables, fiber optic jumpers, etc. It can provide reliable electrical connections and signal transmission to ensure the normal operation of communication systems.

For example, in the construction of communication base stations, C-type copper crimp connectors are used to connect antenna feeders, power lines, etc.

construction industry

In building electrical systems, C-type copper crimp connectors can be used to connect wires and cables, lighting fixtures, sockets, etc. It can facilitate electrical connections quickly and conveniently, improving construction efficiency.

For example, in the electrical installation of home decoration and commercial buildings, C-type copper crimp connectors are widely used for the connection of wire joints.

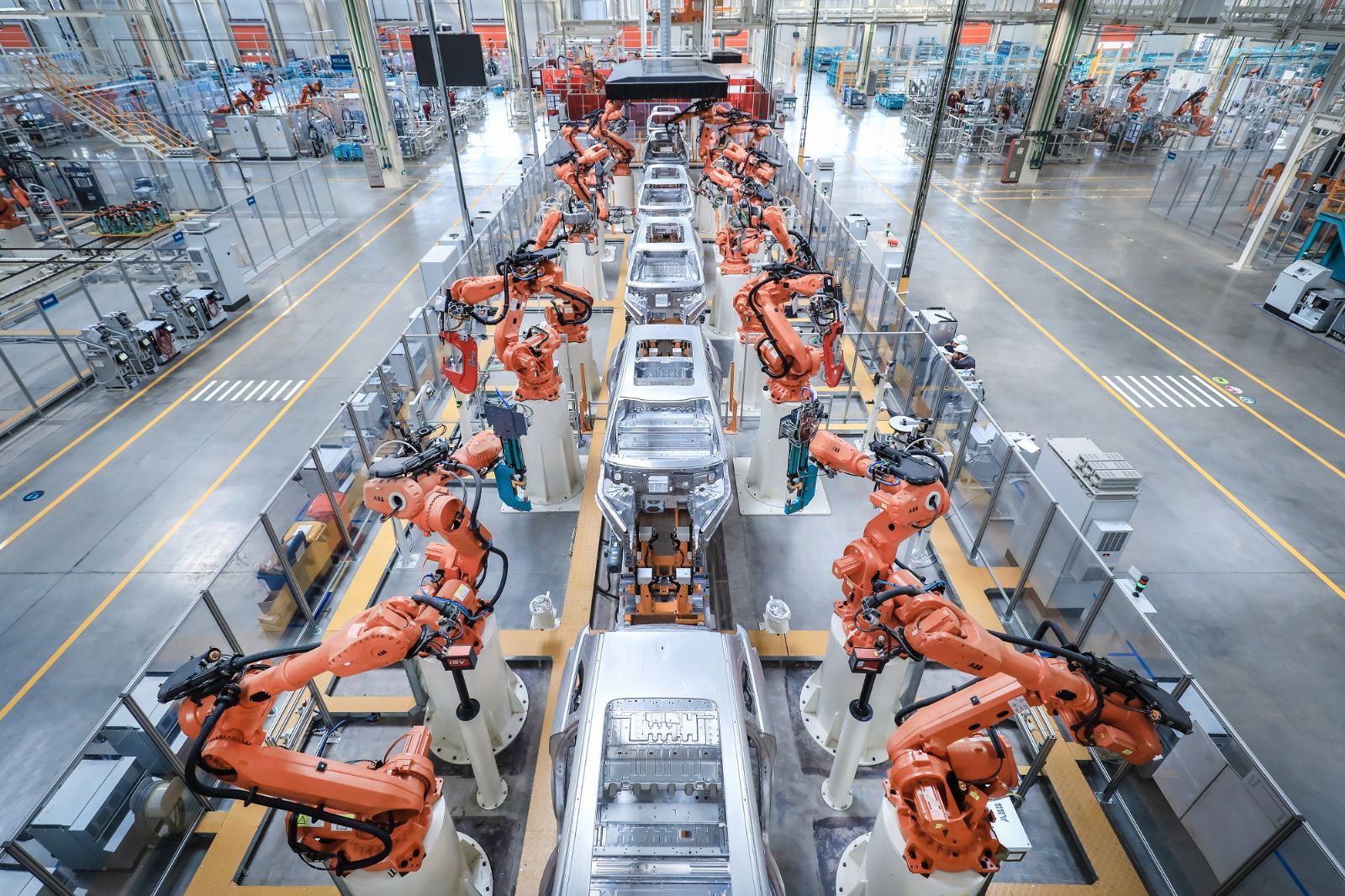

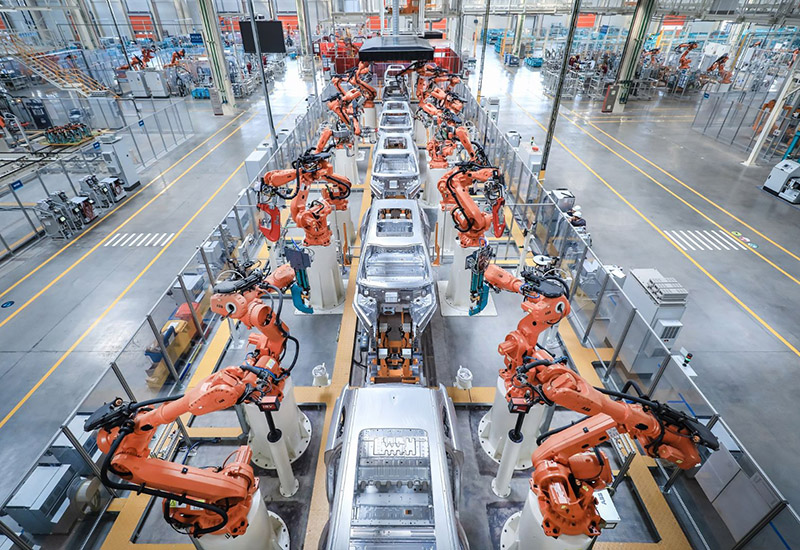

Rail Transit Industry

In the rail transit system, C-type copper crimp connectors can be used to connect the electrical lines, signal systems, etc. of trains. It can withstand vibrations and impacts during train operation, ensuring the reliability of the electrical system.

For example, in the manufacturing and maintenance of rail transit vehicles such as subways and high-speed trains, C-type copper crimp connectors are used to connect various electrical equipment and cables.

4、 Advantages

Reliable connection

The crimping connection method ensures a firm and reliable connection between the connector and the wire, making it less likely to loosen or fall off

18+ Years of Copper Tube Terminals Cnc Machining Experience

• 18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

• Timely delivery

• Years' experience to cooperate with top brands.

• Various kinds of inspection and testing machine for quality assurance.

Applications

New energy vehicles

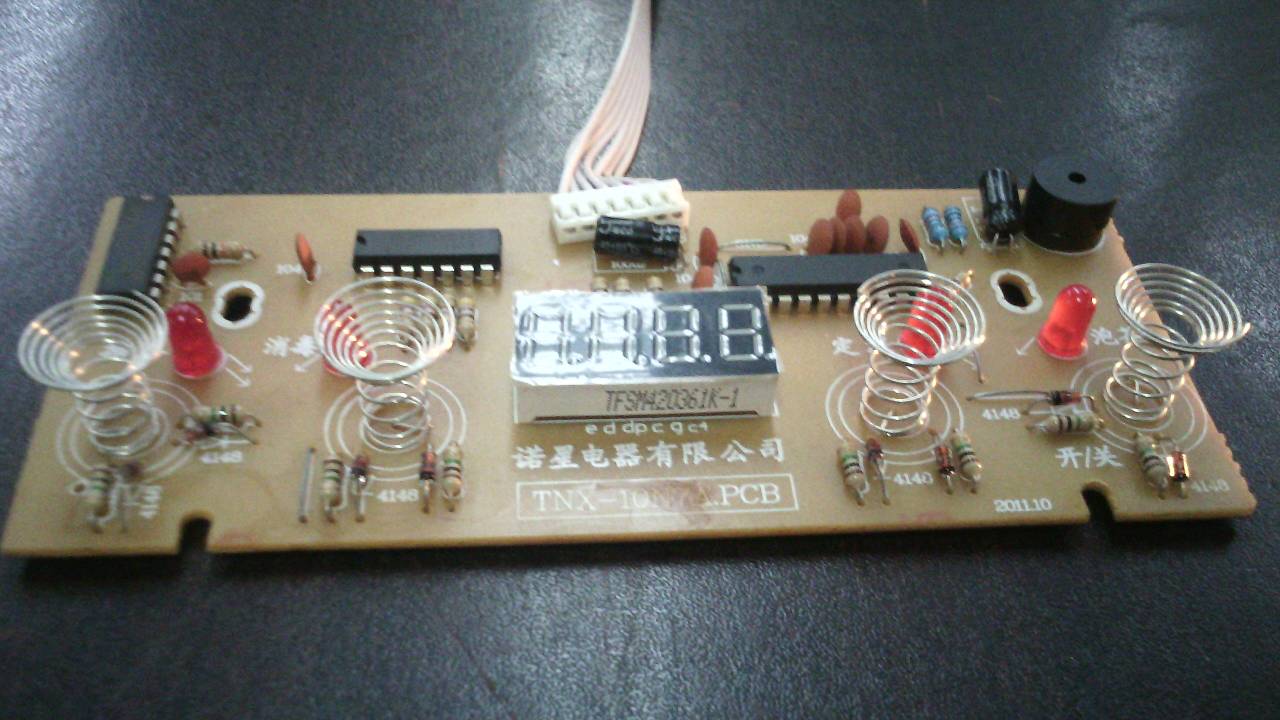

Button control panel

Cruise ship construction

Power switches

Photovoltaic power generation field

Distribution box

One-stop custom hardware parts manufacturer

Customer Communication

Understand customer needs and specifications for the product.

Product Design

Create a design based on customer requirements, including materials and manufacturing methods.

Production

Process the product using precision metal techniques like cutting, drilling, milling, etc.

Surface Treatment

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

Quality Control

Inspect and ensure the products meet specified standards.

Logistics

Arrange transportation for timely delivery to customers.

After-sales Service

Provide support and resolve any customer issues.

FAQ

A: We are a factory.

A: We have 20 years of spring manufacturing experience and can produce many types of springs. Sold at a very cheap price.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: After the price is confirmed, you can ask for samples to check the quality of our products. If you just need a blank sample to check the design and quality. As long as you can afford the express shipping, we will provide you with samples for free.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: It depends on the order quantity and when you place the order.