187 three-pin reel terminal

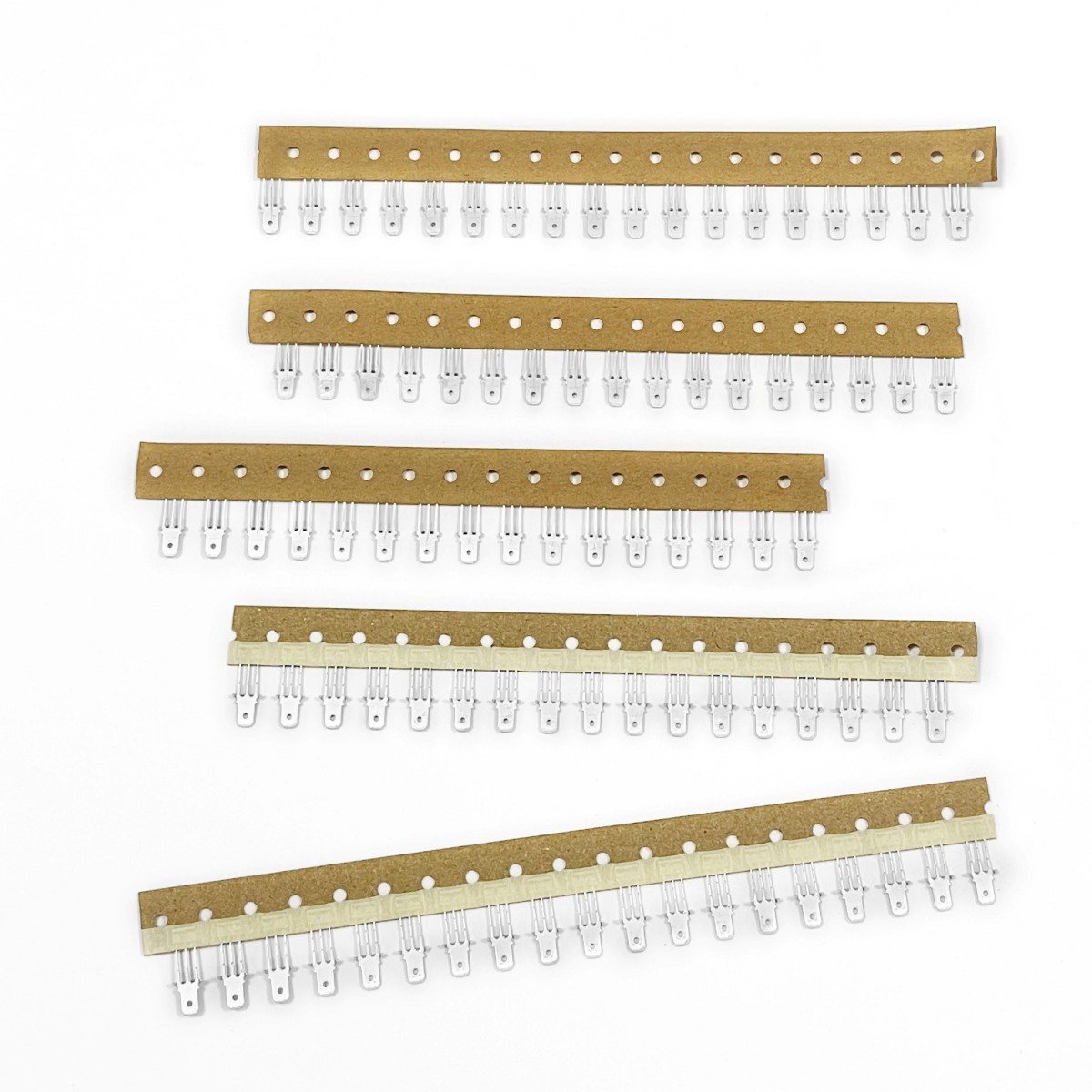

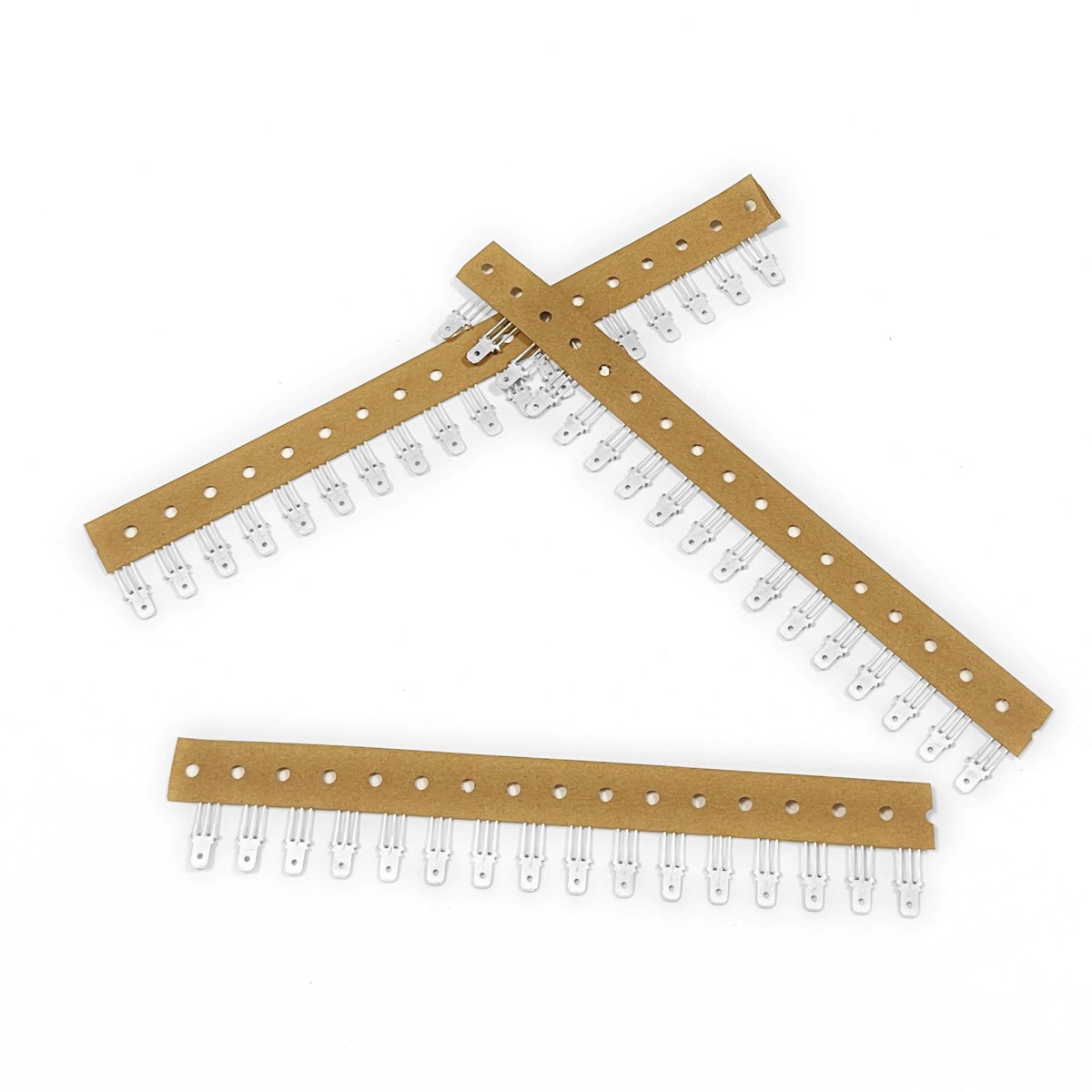

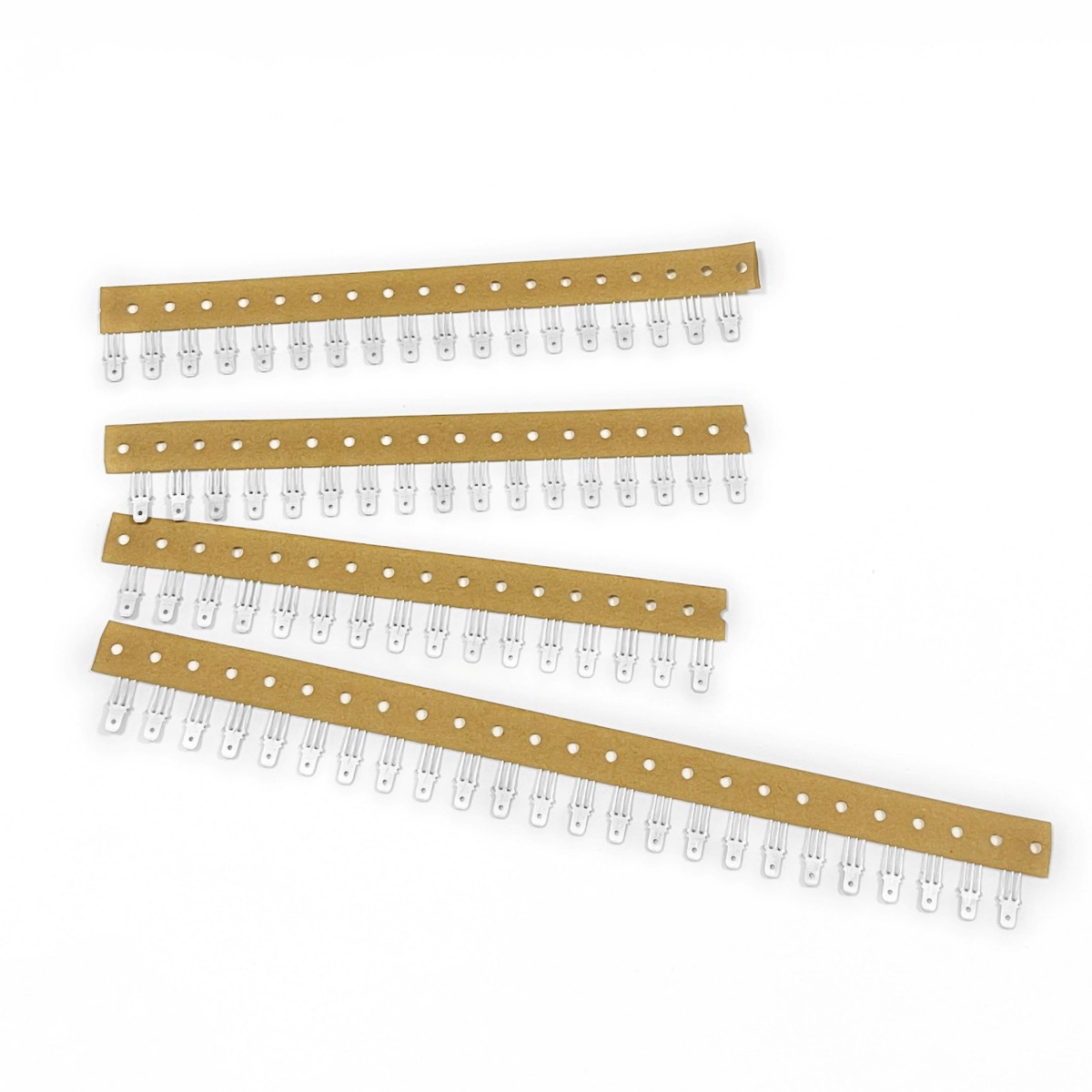

Product pictures

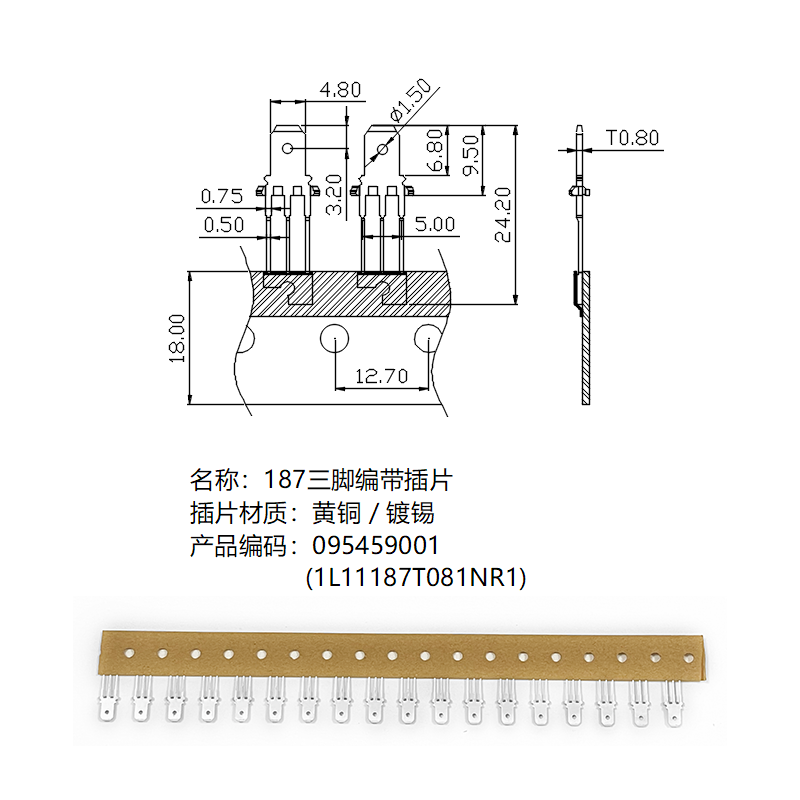

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | silver | ||

| Brand Name: | haocheng | Material: | Copper | ||

| Model Number: | 187 3-PinReel Terminal | Application: | Wire Connecting | ||

| Type: | 187 3-Pin Reel Terminal | Package: | Standard Cartons | ||

| Product name: | Crimp Terminal | MOQ: | 1000 PCS | ||

| Surface treatment: | customizable | Packing: | 1000 PCS | ||

| Wire range: | customizable | Size: | 0.8*4.8*24.2*18 | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 10 | 15 | 30 | To be negotiated | |

Advantages of Copper Tube Terminals

1.Efficient Automated Production

●Reel packaging is optimized for SMT (Surface Mount Technology) automation, enabling fast, precise batch assembly and reducing production downtime.

●Its compact three-pin design minimizes board space usage, ideal for high-density electronic layouts.

2.Superior Electrical Performance

●Ultra-low contact resistance (μΩ-level) ensures minimal signal loss and energy waste.

●High solderability guarantees stable connections during reflow soldering, lowering the risk of defects.

3.Long-Term Durability

●Built with heat-resistant and vibration-resistant materials (e.g., UL/RoHS compliant), it withstands harsh environments and mechanical stress.

●Compliance with international standards (UL, RoHS) ensures reliability in automotive, IoT, and consumer electronics.

4.Versatile Applications

●Widely used in automotive control modules, IoT sensors, and smart consumer devices.

●Supports copper/aluminum wire compatibility for flexible circuit design integration.

18+ Years of Copper Tube Terminals Cnc Machining Experience

•18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

•Timely delivery

•Years' experience to cooperate with top brands.

•Various kinds of inspection and testing machine for quality assurance.

APPLICATIONS

Automobiles

home appliances

toys

power switches

electronic products

desk lamps

distribution box Applicable to

Electric wires in power distribution devices

Power cables and electrical equipment

Connection for

wave filter

New energy vehicles

One-stop custom hardware parts manufacturer

1、Customer communication:

Understand customer needs and specifications for the product.

2、Product design:

Create a design based on customer requirements, including materials and manufacturing methods.

3、Production:

Process the product using precision metal techniques like cutting, drilling, milling, etc.

4、Surface treatment:

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

5、Quality control:

Inspect and ensure the products meet specified standards.

6、Logistics:

Arrange transportation for timely delivery to customers.

7、After-sales service:

Provide support and resolve any customer issues.

FAQ

A: We are a factory.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.

A: Yes, if we have samples in stock, we can provide samples. The associated charges will be reported to you.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.