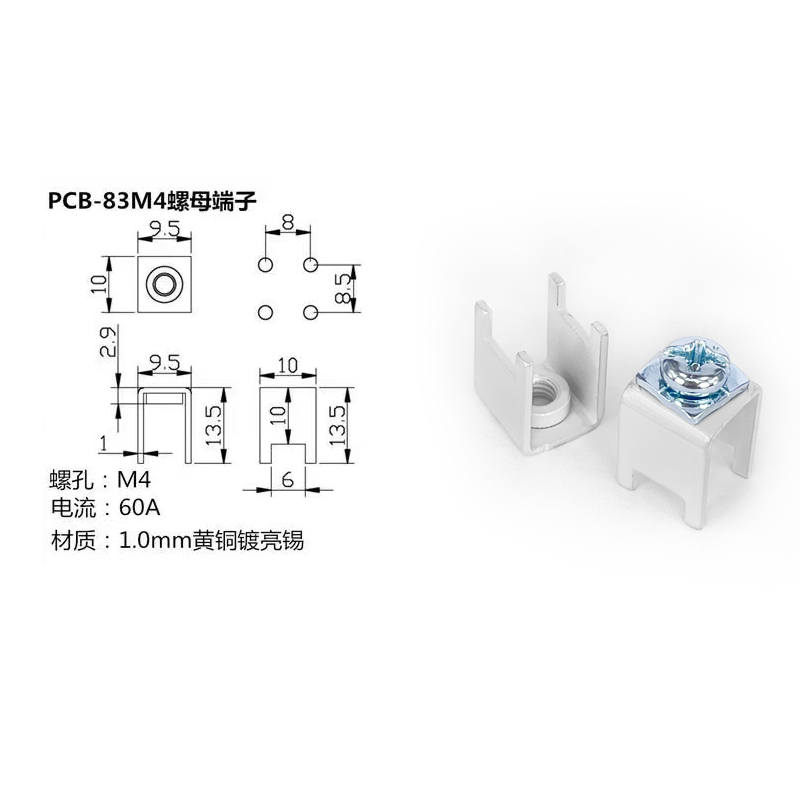

13.5H Welding Station Terminal

Product parameters of Copper Tube Terminals

| Place of Origin: | Guangdong, China | Color: | silver | ||

| Brand Name: | haocheng | Material: | Copper | ||

| Model Number: | 13.5H | Application: | Wire Connecting | ||

| Type: | 13.5H Welding Station Terminal C Product | Package: | Standard Cartons | ||

| Product name: | Crimp Terminal | MOQ: | 1000 PCS | ||

| Surface treatment: | customizable | Packing: | 1000 PCS | ||

| Wire range: | customizable | Size: | 9.5*10*13.5*M4 | ||

| Lead time:The amount of time from order placement to dispatch | Quantity (pieces) | 1-10000 | 10001-50000 | 50001-1000000 | > 1000000 |

| Lead time (days) | 10 | 15 | 30 | To be negotiated | |

Advantages of Copper Tube Terminals

1. Precision-Engineered Structure

• High Compatibility: Specifically designed for 13.5mm-height welding stations, ensuring seamless integration with standard PCBs and precision electronic components.

• Stable Contact Resistance: Robust connections between terminals and wires/PCBs minimize contact resistance and signal.

2. Heat Resistance

• Durable Materials: Copper alloy construction (e.g., phosphor bronze) ensures excellent heat resistance for prolonged welding operations.

• Corrosion-Resistant Coatings: Available in silver/gold plating options for enhanced oxidation resistance and extended lifespan.

3. Safety & Reliability

• Anti-Short Circuit Design: Optimized spacing between terminals reduces the risk of accidental shorts or misoperations.

• Fire-Resistance Compliance: Meets UL/VDE fire safety standards for reliable operation in high-risk environments.

4. Efficient Production Integration

• Automated Compatibility: Supports SMT or wave soldering equipment for streamlined mass production.

• Modular Flexibility: Easily expandable or combinable to adapt to various PCB layouts.

5. Cost-Effectiveness

• Reduced Maintenance Costs: Long-term durability lowers replacement frequency and operational expenses.

• Flexible MOQ Options: Economical for small/medium enterprises (MOQ starts at 100PCS).

• Electronic Manufacturing: Power modules, communication devices.

• Industrial Automation: Control boards in automation systems.

• High-Reliability Fields: Automotive electronics, medical equipment.

18+ Years of Copper Tube Terminals Cnc Machining Experience

•18 Years' R&D Experiences in spring, metal stamping and CNC parts.

• Skilled and technical engineering to ensure the quality.

•Timely delivery

•Years' experience to cooperate with top brands.

•Various kinds of inspection and testing machine for quality assurance.

APPLICATIONS

Automobiles

home appliances

toys

power switches

electronic products

desk lamps

distribution box Applicable to

Electric wires in power distribution devices

Power cables and electrical equipment

Connection for

wave filter

New energy vehicles

One-stop custom hardware parts manufacturer

1、Customer communication:

Understand customer needs and specifications for the product.

2、Product design:

Create a design based on customer requirements, including materials and manufacturing methods.

3、Production:

Process the product using precision metal techniques like cutting, drilling, milling, etc.

4、Surface treatment:

Apply appropriate surface finishes like spraying, electroplating, heat treatment, etc.

5、Quality control:

Inspect and ensure the products meet specified standards.

6、Logistics:

Arrange transportation for timely delivery to customers.

7、After-sales service:

Provide support and resolve any customer issues.

FAQ

A: We are a factory.

A: We usually quote within 24 hours after receiving your inquiry. If you are in a hurry to get a price, please let us know in your email so we can prioritize your inquiry.

A: Generally 5-10 days if the goods are in stock. 7-15 days if the goods are not in stock, by quantity.